Thomas Wilhelm

Ph.D. Student and Researcher

Microsystems Engineering Ph.D. Program

Rochester Institute of Technology

Research Project: III-V Nanofabrication by Metal-Assisted Chemical Etching

Thomas Wilhelm

Ph.D. Student and Researcher

Microsystems Engineering Ph.D. Program

Rochester Institute of Technology

Research Project: III-V Nanofabrication by Metal-Assisted Chemical Etching

Bio

Thomas Wilhelm is a student in the Microsystems Engineering Ph.D. Program, and a member of the Center for Detectors and the NanoPower Research Laboratories. He completed his B.S. degree in Physics at Calvin College in 2011. His areas of undergraduate research included the avoided crossing in the normal-mode frequencies of a Wilberforce pendulum, optical heterodyne spectroscopy, and using laser light scattering to measure the effects of monosaccharides on the transition temperatures of phospholipids. Later in 2011, Thomas began his graduate studies at Northern Illinois University where he studied Applied Physics. His areas of research included simulations of field-emission due to nanocathode arrays (in collaboration with the Massachusetts Institute of Technology), and characterization of inorganic silicon oxide molecules deposited onto organic POPC lipid bilayers via chemical vapor deposition (CVD) using scanning tunneling electron microscopy (STEM), energy dispersive x-ray spectroscopy (EDXS), and high angular annular dark field (HAADF) data collected at the Electron Microscopy Center at Argonne National Laboratory (in collaboration with Oklahoma State University). Afterwards, Thomas attended Lehigh University where he completed his M.Eng. in Mechanical Engineering in 2014.

Thomas' industry experience includes an extended, one-year internship as a Product Development Engineer before coming to Rochester, NY to accept a position as an Optical Metrology Engineer. Thomas joined RIT's Microsystems Engineering Ph.D. Program in January of 2016.

Thomas is a member of the Mohseni Research Group, working under Dr. Parsian Mohseni on novel, top-down methods for fabrication of III-V and Si nanostructures using metal-assisted chemical etching (MacEtch). MacEtch is an anisotropic, wet-etching technique that relies on catalytic oxidation of a semiconductor substrate underneath a patterned noble metal layer, and preferential dissolution of the selectively oxidized regions. An inherent consequence of this technique is vertical etching of the underlying semiconductor material. Devices consisting of the resulting high aspect-ratio nanostructures have applications in high-efficiency photovoltaics and optoelectronics.

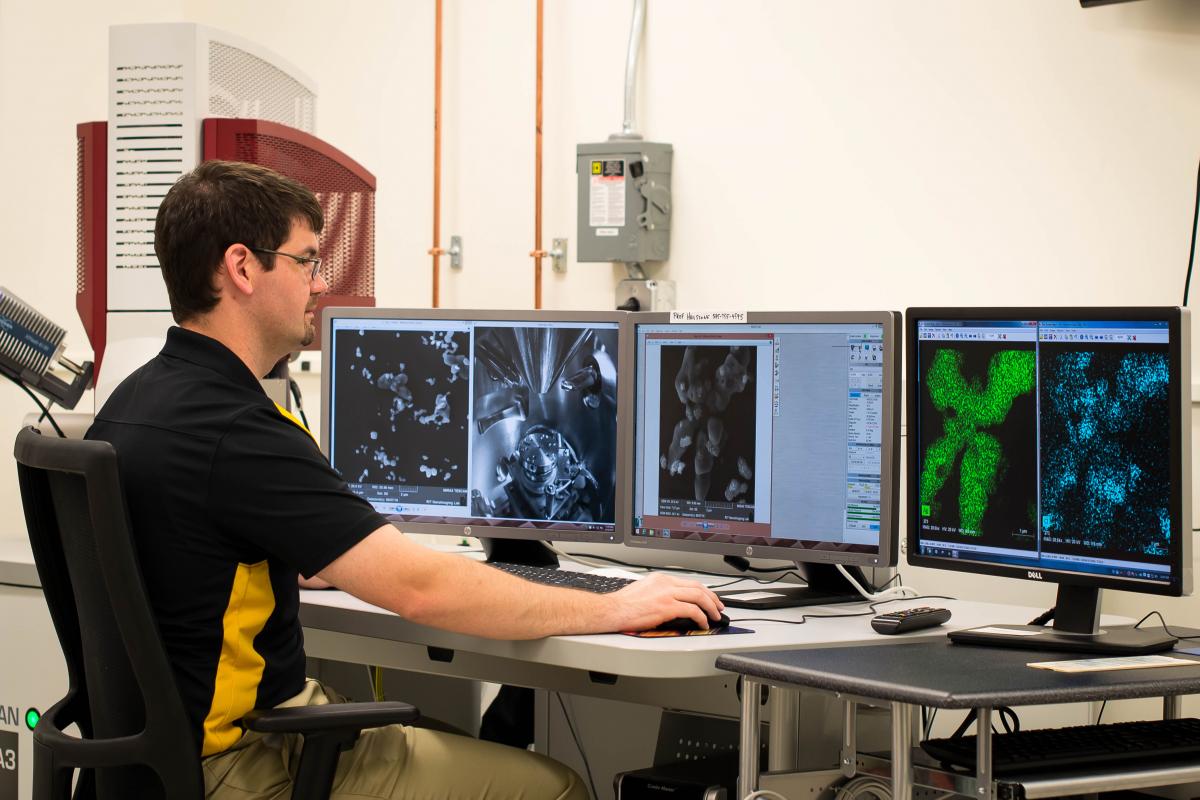

Thomas is seen here using the TESCAN MIRA3 scanning electron microscope (SEM; RIT NanoImaging Lab), where he is analyzing a sample containing Ag nanoparticles on a GaAs substrate for use in MacEtch experiments.