Salman Pervaiz

Director of Materials and Advanced Manufacturing Research Center - MAMRC and Associate Professor of Mechanical Engineering

Salman Pervaiz

Director of Materials and Advanced Manufacturing Research Center - MAMRC and Associate Professor of Mechanical Engineering

Bio

Dr. Pervaiz received his Ph.D. in Production Engineering from KTH Royal Institute of Technology, Sweden in 2015. While pursuing his Ph.D., Dr. Pervaiz has worked on a Swedish Industry (Accu-Svenska AB) supported project for the development of an advanced minimum quantity cooling lubrication (MQCL) system to facilitate the sustainable and environment friendly machining of aeronautic titanium alloy (Ti6Al4V). His current research interests are in the general area of design and manufacturing, including different advanced topics such as sustainable manufacturing, metal cutting, energy efficient machining, machinability improvement of difficult-to-cut materials, development and optimization of custom made cutting tools and computer aided designing/ manufacturing etc.

Dr. Salman Pervaiz is an accomplished educator, researcher, and leader with over 15 years of experience in materials science, sustainable manufacturing, and additive manufacturing (3D printing). He was recognized among the world’s top 2% of scientists (Stanford University Rankings, 2024-2025), reflecting his significant scientific contributions, innovation, and global impact in advanced manufacturing.

Dr. Pervaiz is highly qualified in developing and optimizing sustainable solutions for the manufacturing sector, with deep expertise in high-performance aeronautical materials such as titanium alloys, nickel alloys, and composites. His achievements include receiving a Letter of Commendation from The Proceedings of the Institution of Mechanical Engineers – Journal of Engineering Manufacture for his contributions to the field. He has been an invited speaker at prestigious platforms, including delivering a seminar on 3D Printing at Dubai Police GHQ Innovation Summer (2022) and a keynote at RTA’s Transport Research and Innovation Pavilion (2023).

As a prolific author, Dr. Pervaiz has published 130+ peer-reviewed research articles (80 journal papers and 54 conference proceedings) and delivered 35+ international conference presentations across the US, Europe, Singapore, and the UAE. He is also recognized for his ability to effectively communicate complex engineering concepts to diverse audiences, ranging from academic peers to business leaders.

Dr. Pervaiz has demonstrated strong leadership and collaboration skills within academia, industry, and professional societies. He is a founding member and current Chair of the ASME UAE Section, where he coordinated all student sections and lead the national ASME 3D Printing Competition. Internationally, Dr. Pervaiz serves as Chair/ Co-chair for the Advanced Manufacturing Track at ASME IMECE 2024, 2025 & 2026 and has organized multiple symposia on circular economy, sustainable production, and advanced machining processes since 2019.

Through his extensive research, leadership, and professional service, Dr. Pervaiz continues to advance the future of manufacturing innovation, education, and global industry collaboration.

Select Scholarship

1) S. Ali, M. Alshihabi, L. Beard, I. Deiab, and S. Pervaiz, “ Dual-Stimuli Responsive and Sustainable PLA/APHA/TPU Blend for 4D Printing.” Macromolecular Rapid Communications 46, no. 21 (2025): e00414. https://doi.org/10.1002/marc.202500414

2) John JS, Pervaiz S. Structural Integrity Assessment of Stainless Steel Fabricated by GMAW-Assisted Wire Arc Additive Manufacturing. Technologies. 2025; 13(9):392. https://doi.org/10.3390/technologies13090392

3) Aamir, Y., Pervaiz, S. Optimizing PLA-Sun-Dried Olive Leaf Waste Filament Blends Fabrication Using Taguchi-Grey Relational Analysis. Fibers Polym 26, 5223–5247 (2025). https://doi.org/10.1007/s12221-025-01149-y

4) Aqib Mashood Khan, Salman Pervaiz, Muhammad Jamil, Wei Zhao, Longhui Meng, New Investigations on the performance Enhancement of Cryogenic-LN2 assisted sustainable milling of titanium alloy, Manufacturing Letters, Volume 44, Supplement, 2025, Pages 396-404, https://doi.org/10.1016/j.mfglet.2025.06.047

5) Alshibi, A., Pervaiz, S., Khan, A.M. et al. A comprehensive evaluation of tool wear progression and built-up layer formation in sustainable dry machining of AZ61 magnesium alloy. Int J Adv Manuf Technol 138, 3021–3039 (2025). https://doi.org/10.1007/s00170-025-15607-7

6) John JS, Pervaiz S. Towards a Low-Carbon Future: Evaluating 3D Printing’s Alignment with Sustainable Development Goal 13. Sustainability. 2025; 17(19):8837. https://doi.org/10.3390/su17198837

7) Ali S, Deiab I, Pervaiz S, Eltaggaz A. Development of sustainable polymer composite with agro-industrial residue for biomedical applications. Polym Eng Sci. 2025; 65(4): 1922-1933. doi:10.1002/pen.27123

8) Dehestany, A., Pervaiz, S. Multi-parametric optimization of convex spherical surface drilling of Ti6Al4V using finite element model and Taguchi coupled desirability function analysis. Int J Interact Des Manuf 19, 2399–2414 (2025). https://doi.org/10.1007/s12008-024-01790-6

9) Ali, S., Nouzil, I., Mehra, V. et al. Integrated optimization scheme for 3D printing of PLA-APHA biodegradable blends. Prog Addit Manuf 10, 875–886 (2025). https://doi.org/10.1007/s40964-024-00684-z

10) Shafahat Ali, Ibrahim Deiab, Salman Pervaiz, Optimizing the properties of PHBV/PBAT blend for additive manufacturing, Procedia CIRP,

Volume 131, 2025, Pages 7-12, https://doi.org/10.1016/j.procir.2024.09.004.

Currently Teaching

Featured Work

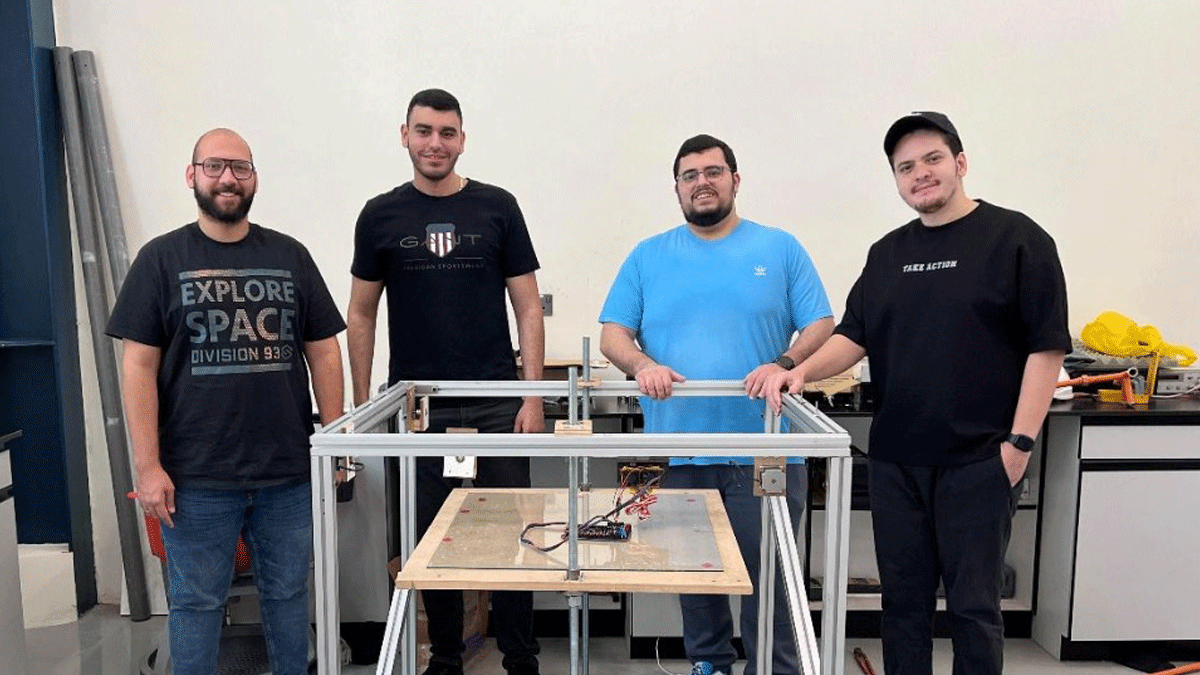

Design and Fabrication of Large Scale 3D Printer

Multidisciplinary Senior Design Project ’24

Building Innovation Layer by Layer

3D Printing Filament

Multidisciplinary Senior Design Project ’24

Reimagining 3D Printing with Sustainability