Dua Weraikat

Department Coordinator and Assistant Professor of Industrial Engineering

Dua Weraikat

Department Coordinator and Assistant Professor of Industrial Engineering

Education

Doctor of Philosophy, Industrial Engineering from Concordia University, Montreal, Quebec, Canada; Masters of Science, Industrial Engineering- Manufacturing from University of Jordan, Amman, Jordan; Bachelor of Science, Industrial Engineering- Management from Jordan University of Science and Technology, Irbid, Jordan

Bio

Dr. Weraikat teaches courses in operations research, decision analysis, production planning, and production control, and has been actively involved in curriculum development, accreditation, and program coordination. Her research focuses on applying artificial intelligence, machine learning, optimization, and data analytics to address challenges in supply chain resilience, healthcare systems, smart farming, and sustainability.

Dr. Weraikat has published widely in high-impact journals and international conferences, with notable contributions to pharmaceutical supply chain resilience and sustainable industrial practices. She also serves on the IISE Operations Research Division Board (2025–2027) and founded the IISE Student Chapter at RIT Dubai. Her dedication to student engagement and professional service has earned her multiple awards, including the Outstanding Global Faculty Advisor Award (IISE, 2024), the Arabian Peninsula Regional Faculty Advisor Award (IISE, 2024 & 2025), and several Gold Awards in the IISE Chapter Recognition Program (2023–2025).

Select Scholarship

Some of Recent Publication:

1. Laith, H., Weraikat, D., Khan, S., (2025) The Role of Digitalization Technologies in Enhancing Supply Chain Performance in the Service Industry: Identifying the Current Research Gaps, Journal of Information & Knowledge Management (Q2), 2550077. https://doi.org/10.1142/S0219649225500777. Number of citations 1.

2. Weraikat, D. and Alhourani, S., (2025) Systematic Review of Machine Learning and Artificial Intelligence in Pharmaceutical Supply Chain (PSC) Resilience: Identifying Gaps and Future Research Directions. Sustainability 17(14), 6591 (Q1). https://doi.org/10.3390/su17146591. Number of citations 11.

3. O. Al Meheiri and D. Weraikat, (2025). Integration of Renewable Energy Strategies: A Case in Dubai South. Sustainability 17(13) (Q1), 6093. https://doi.org/10.3390/su17136093. Number of citations 1.

4. Weraikat, D.; Šori?, K.; ?agar, M.; Soka?, M. (2024). Data Analytics in Agriculture: Enhancing Decision-Making for Crop Yield Optimization and Sustainable Practices. Sustainability, 16(17) (Q1), 7331. https://doi.org/10.3390/su16177331. Number of citations 10.

5. Weraikat, D., Zanjani, M. K., & Lehoux, N. (2019). Improving sustainability in a two-level pharmaceutical supply chain through Vendor-Managed Inventory system. Operations Research for Health Care (Q2), 21, 44-55. https://doi.org/10.1016/j.orhc.2019.04.004, Number of citations 106.

6. D. Weraikat, M. Zanjani, N. Lehoux (2016) “Two-echelon Pharmaceutical Reverse Supply Chain Coordination with Customers Incentives,” International Journal of Production Economics (Q1), 176, 41-52. https://doi.org/10.1016/j.ijpe.2016.03.003, Number of citations 118.

7. D. Weraikat, M. Zanjani, N. Lehoux (2016) “Coordinating a Green Reverse Supply Chain in Pharmaceutical Sector by Negotiation,” Computer and Industrial Engineering Journal (Q1), 93, 67-77. https://doi.org/10.1016/j.cie.2015.12.026 , Number of citations 96.

Currently Teaching

Featured Work

Automated Systems for Composting Paper Towels

Multidisciplinary Senior Design Project ’25

Smart composting meets sustainability

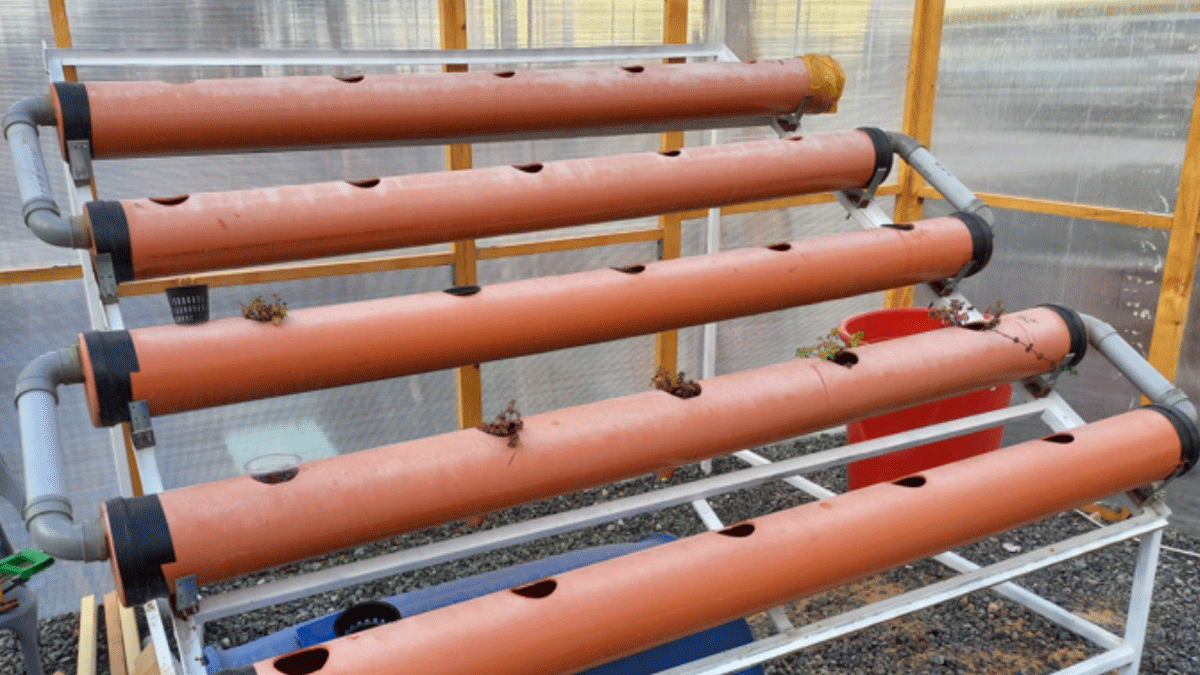

Smart Farming by Fully Automated Hydroponic System

Multidisciplinary Senior Design Project ’24

Smart Farming, No Soil Needed