8,037,777

Structurally Compliant Microbearing Devices and Methods Thereof

Patent Number

Issue Date

Inventor(s)

Stephen Boedo; William Grande

Document

Download PDF for patent 8,037,777Synopsis

Patent 8,037,777 B2 describes groundbreaking structurally compliant microbearing devices and methods for their fabrication. This invention offers a transformative solution to the inherent limitations of conventional microbearings, specifically addressing their susceptibility to wear and early seizure, thereby paving the way for significantly more durable and reliable micro-scale rotating components across numerous applications.

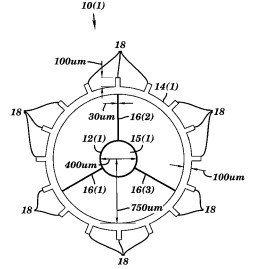

A core novel aspect of this invention is the introduction of engineered structural compliance into the microbearing design. Unlike rigid traditional bearings, this technology features components, such as an outer ring with deformable blades and an inner ring with structural elasticity, that are designed to deform or deflect under operational loads. This inherent flexibility dramatically reduces localized stress concentrations and minimizes friction and wear by distributing forces more evenly. The result is a microbearing device with significantly increased resistance to wear and premature failure, leading to an extended operational lifespan and enhanced overall reliability. The manufacturing process further highlights its innovation, involving the precise etching of a substrate, such as a silicon wafer, to create the intricate housing assembly and shaft. This method enables the batch fabrication of these robust micro-scale components, making the technology economically viable for mass production. Furthermore, the ability to tailor fastener designs (e.g., straight or spiral) provides additional control over the bearing's translational motion and rotational efficiency, allowing for customization to specific performance requirements.

The commercial potential for this structurally compliant microbearing technology is substantial, poised to revolutionize various industries that rely on miniaturized rotating parts, by providing previously unattainable levels of durability and performance. Possible applications include:

-

Microelectromechanical Systems (MEMS): This technology is critical for improving the longevity and reliability of a wide range of MEMS devices that incorporate moving or rotating elements, such as micro-motors, micro-pumps, micro-turbines, and various micro-sensors (e.g., gyroscopes, accelerometers used in consumer electronics and industrial controls).

-

Miniaturized Robotics and Medical Devices: Essential for enabling precise, durable, and reliable movement in miniature robots designed for inspection, exploration, or intricate surgical procedures, as well as in implantable medical devices where long-term operation is paramount.

-

Data Storage and Consumer Electronics: For developing more robust and longer-lasting spindle motors in miniaturized hard disk drives or other data storage solutions, and for enhancing the durability of moving components in compact consumer electronics like camera stabilization systems or haptic feedback mechanisms.

-

Precision Instruments and Optics: Applicable in highly sensitive and precise rotational stages within miniature optical systems, scientific instruments, and micro-actuators, where stability and minimal wear are crucial for accurate measurements and operations.

-

Aerospace and Defense: For enhancing the durability and performance of micro-drones, miniature satellite components, and other compact aerospace systems that require reliable moving parts to operate in demanding environments.

-

Wearable Technology: Could lead to more robust and reliable mechanisms in smartwatches, fitness trackers, and other wearable devices that incorporate micro-scale moving components, improving product lifespan and user satisfaction.

This patent offers a fundamental advancement in micro-scale mechanics, providing a compelling opportunity for licensees to develop and commercialize next-generation products that demand exceptional durability and precision in a compact form factor.