8,581,480

Self-Regenerating Particulate Trap Systems for Emissions and Methods Thereof

Patent Number

Issue Date

Inventor(s)

Ali Ogut; Cheng Chen

Document

Download PDF for patent 8,581,480Synopsis

Patent US 8,581,480 B2 describes self-regenerating particulate trap systems for emissions and methods thereof. This invention addresses the challenge of particulate matter accumulation in exhaust systems, particularly from diesel engines, by providing a novel approach to continuously and efficiently remove trapped particulates without requiring external heating elements or significant energy consumption.

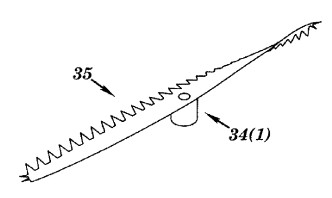

A key novel aspect of this invention is the integration of a conductive probe directly into the particulate trap, allowing for in-situ electrical regeneration of the trap. Unlike conventional systems that rely on periodic, energy-intensive regeneration cycles (e.g., by raising exhaust temperature or using fuel-borne catalysts), this system utilizes electrical energy to heat the trapped particulates directly, leading to their oxidation and removal. The conductive probe, designed with features like threaded teeth or a contoured surface, ensures efficient electrical contact and uniform heating of the accumulated soot. This direct electrical heating approach offers several significant advantages:

-

Continuous and Efficient Regeneration: The system enables continuous regeneration of the particulate filter, eliminating the need for high exhaust temperatures or separate regeneration cycles. This improves fuel economy by reducing the backpressure on the engine and avoids the operational downtime associated with passive or active regeneration methods.

-

Reduced Energy Consumption: By directly heating the particulates via electrical resistance, the system minimizes the energy required for regeneration compared to methods that heat the entire exhaust system. This contributes to overall energy efficiency.

-

Enhanced Durability and Longevity: The continuous and controlled regeneration process helps prevent excessive soot buildup and thermal runaway, which can damage traditional filters. This can lead to increased durability and a longer lifespan for the particulate trap.

-

Versatile Application: The design of the conductive probe and its detachable securing mechanism allows for integration into various emissions treatment housings, making it adaptable to different engine types and exhaust system configurations. The probe can also be easily replaced.

-

Reduced Emissions: By ensuring consistent particulate removal, the system helps maintain the efficiency of emissions control, contributing to cleaner exhaust and compliance with environmental regulations.

The commercial potential for this self-regenerating particulate trap technology is substantial across various sectors focused on emissions control and engine efficiency:

-

Automotive Industry: Particularly for diesel vehicles (cars, trucks, buses), this technology offers a compelling solution for meeting stringent particulate matter emission standards while simultaneously improving fuel economy and reducing maintenance costs associated with traditional DPF regeneration.

-

Heavy-Duty Equipment: Construction machinery, agricultural vehicles, and industrial equipment often operate in demanding conditions with high particulate emissions. This invention provides a robust and efficient solution for these applications, enhancing operational efficiency and environmental compliance.

-

Marine and Rail Transport: Diesel engines are prevalent in marine vessels and locomotives. This self-regenerating trap can offer significant advantages in terms of continuous operation, fuel efficiency, and reduced emissions in these sectors.

-

Stationary Power Generation: Diesel generators used for backup power or prime power generation can also benefit from this technology by reducing their particulate emissions and operating more efficiently.

-

Aftermarket and Retrofit Solutions: The adaptable design of the system suggests potential for aftermarket solutions or retrofits to existing vehicles and equipment, providing a cost-effective way to upgrade emissions control.

This invention provides a durable, efficient, and highly versatile solution for managing particulate emissions, capable of meeting the rigorous demands of diverse applications where environmental compliance, operational efficiency, and reduced maintenance are paramount. Its unique electrical regeneration architecture positions it as a compelling alternative to current particulate trap technologies.