8,991,153

Self-Regenerating Particulate Trap System for Emissions and Methods Thereof

Patent Number

Issue Date

Inventor(s)

Ali Ogut; Chen Cheng

Document

Download PDF for patent 8,991,153Synopsis

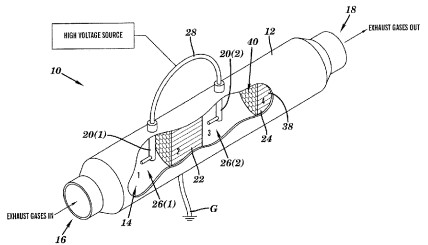

Patent US 8,991,153 B2 describes self-regenerating particulate trap systems for emissions and methods thereof. This invention offers a novel and effective solution for reducing particulate matter and other harmful emissions from exhaust streams, particularly in internal combustion engines, by continuously regenerating the trap without requiring external energy sources or frequent maintenance.

A key novel aspect of this invention is its self-regenerating capability, which eliminates the need for manual or energy-intensive regeneration processes common in conventional particulate filters. The system integrates an electrostatic charging mechanism that imparts a charge to particulate matter in the exhaust stream. Downstream from the charging system, an attraction system, which may consist of oppositely charged or grounded surfaces, collects these charged particles. Concurrently, the charging system also generates reactive radicals that can oxidize the trapped particulate matter. This continuous oxidation process effectively "cleans" the trap, preventing clogging and maintaining optimal filtration efficiency over extended periods. This integrated approach bypasses the energy consumption and operational downtime associated with active regeneration.

The commercial potential for this self-regenerating particulate trap system is substantial across various industries concerned with emissions control and air quality:

-

Automotive Industry: For internal combustion engines (gasoline and diesel) in passenger vehicles, trucks, and buses, this technology can significantly reduce particulate emissions, helping manufacturers meet increasingly stringent environmental regulations (e.g., Euro 6, EPA standards). Its self-regenerating nature offers a maintenance-free solution for consumers and a cost-effective alternative for fleet operators by eliminating the need for periodic filter cleaning or replacement.

-

Off-Road Equipment and Heavy Machinery: Construction equipment, agricultural machinery, and mining vehicles often operate in sensitive environments and are significant sources of particulate emissions. This system can be integrated into their exhaust systems to achieve compliance and reduce environmental impact without compromising operational uptime due to regeneration cycles.

-

Marine and Rail Transport: Large diesel engines used in ships and locomotives contribute substantially to air pollution. This technology offers a viable solution for reducing their particulate emissions, supporting cleaner transportation and potentially enabling operation in emission control areas.

-

Stationary Power Generation: Diesel generators and other stationary combustion sources used for power generation, especially in remote areas or for backup power, can benefit from this system to lower their environmental footprint and comply with local air quality regulations.

-

Industrial Processes: Certain industrial processes that generate particulate emissions, such as some manufacturing or waste-to-energy facilities, could integrate this technology to improve their emission control systems, reduce environmental liabilities, and enhance their public image.

-

Aftermarket Solutions: The technology could be developed into an aftermarket product for existing vehicles and machinery to upgrade their emission control capabilities without requiring complex modifications to the engine management system.

This invention provides a robust, low-maintenance, and highly efficient solution for particulate matter reduction, addressing a critical environmental and regulatory challenge. Its self-regenerating mechanism offers a compelling economic and operational advantage over existing technologies, positioning it for wide adoption across various combustion-driven applications.