US 10875979

FORMATION AND PROPERTIES OF CELLULAR FOAM FIBROUS MATERIAL

Patent Number

Issue Date

Inventor(s)

Changfeng Ge; Mark Olles; Kevin Cosgrove; Carlos A. Diaz;

Document

Download PDF for patent US 10875979Synopsis

Patent US 10,875,979 B2 describes a novel foaming process for converting fibrous material, including agricultural waste and other fiber-based biomass, directly into a cellular foam structure with cushioning properties. This invention offers a sustainable alternative to conventional petroleum-based foams like Expanded Polystyrene (EPS), Expanded Polyethylene (EPE), Expanded Polypropylene (EPP), and Polyurethane (PU).

The core innovation lies in the specific method of foam formation, which utilizes fibrous material as structural "struts" bonded together into a stable cellular network.

The process involves several key steps:

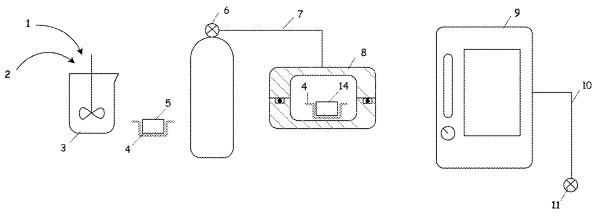

Mixing: Fibrous material is mixed with a solvent-based binding agent to form a mixture. The fibrous raw material can be shredded into small sizes to act as cellular struts. Water can also be used, absorbed into the lignocellulose raw material before adding binding agents.

Saturation: The mixture is saturated with a pressurized gas (e.g., nitrogen, carbon dioxide) to form a gas-saturated mixture. This saturation typically occurs at high pressures, such as 1500 psi for 30 minutes, to ensure gas sorption.

Expansion: The gas-saturated mixture is expanded by rapidly reducing the pressure of the pressurized gas, which induces cell nucleation and creates voids within the fibrous material. This is referred to as primary expansion through a pressure drop. The mixture can be placed in a mold that constrains expansion, allowing for a net-shaped foam.

Curing: The expanded mixture is then cured, often in a vacuum oven under controlled temperature, to set the fibrous material and drive off the solvent (or water), providing a stable network with cushioning properties. Secondary expansion, curing, and stabilization can occur in a vacuum tunnel.

A significant novel aspect of this invention is the ability to directly convert biomass and agricultural waste into a functional foam, leveraging natural resources as the primary structural component rather than relying on petroleum-derived polymers. The resulting foam's structure and properties can be controlled by adjusting parameters such as the gas mixture (nitrogen, carbon dioxide composition), saturation time, saturation pressure, and initial mixture composition.

The commercial potential of this invention is significant due to its sustainable nature, cost-effectiveness (by utilizing waste materials), and versatile cushioning properties.

Possible applications for this cellular foam fibrous material include:

Packaging Materials: As a sustainable alternative to traditional foam packaging, it could be used for protecting fragile goods during shipping, offering a biodegradable and environmentally friendly option for various industries.

Insulation: The cellular structure provides excellent thermal and acoustic insulation properties, making it suitable for building materials, refrigeration units, and automotive applications, contributing to energy efficiency.

Automotive Industry: For interior components, sound dampening, and lightweight structural elements, this material could reduce vehicle weight, improve fuel efficiency, and enhance recyclability.

Construction: As a lightweight filler, insulation, or cushioning layer in building applications, potentially improving structural integrity while offering sustainable characteristics.

Furniture and Bedding: The cushioning properties make it ideal for use in mattresses, seating, and other upholstered products, providing a greener alternative for consumer goods.

Filtration Media: The porous structure could be engineered for various filtration applications, including air and water purification, due to its fibrous nature.

Biomedical Applications: Potentially in wound dressings, drug delivery systems, or scaffolds for tissue engineering, depending on the specific fibrous materials and binding agents used, given its bio-based origin.

This technology presents a compelling opportunity for licensees looking to innovate with sustainable materials, reduce their environmental footprint, and tap into growing markets demanding eco-friendly products with robust performance characteristics.