US 10907265

FLOW-REGULATED GROWTH OF NANOTUBES

Patent Number

Issue Date

Inventor(s)

Jiandi Wan; Rong Fan; Zihao Wang

Document

Download PDF for patent US 10907265Synopsis

Patent US 10,907,265 B2 describes a method for the flow-regulated growth of nanotubes using microfluidic electrochemical anodization. The invention presents a novel approach to overcome the limitations of conventional nanotube growth methods, particularly the lack of control over morphological properties and spatial homogeneity. By introducing a laminar electrolyte flow within a microfluidic device, this method enables precise control over the growth rate, length, diameter, and crystal orientation of the resulting nanotubes.

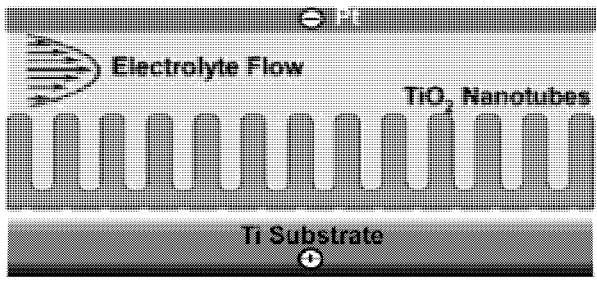

The method utilizes a microfluidic device with a metal anode (e.g., Titanium) and a metal cathode (e.g., Platinum) separated by an electrical insulator. An electrolyte solution flows through a microchannel between the anode and cathode, while an electrical current causes the electrochemical anodization growth of nanotubes on the anode's surface. A key discovery is that increasing the flow rate of the electrolyte linearly increases the steady-state current density, which in turn enhances the rate of nanotube growth. This flow-regulated process can increase the length of the nanotubes by up to 400% compared to static conditions. Furthermore, the invention allows for the suppression of unwanted oxide layer growth, which negatively affects nanotube properties, by maintaining a laminar flow with a high Peclet number.

A significant innovation described is the ability to control the spatial distribution and alignment of the nanotubes. By manipulating the flow velocity profile within the microchannel, uniform nanotube dimensions can be achieved across the channel. The patent also details a method to produce both vertically and horizontally aligned nanotubes on a single substrate by depositing a titanium thin-film on a non-conductive silicon wafer. This dual-alignment capability opens up new possibilities for creating complex hierarchical nanostructures.

The commercial potential of this invention is substantial, as the ability to precisely control nanotube properties and alignment addresses a critical need in advanced material manufacturing. Vertically and horizontally aligned nanotubes with controlled dimensions are desirable for a range of high-performance applications. Potential applications include:

-

Nanoelectronics and Sensors: The ability to grow nanotubes directly onto silicon substrates could facilitate the integration of these materials into next-generation electronic devices and highly sensitive sensors. The enhanced control over alignment and morphology could lead to improved device performance and reliability.

-

Solar Cells: The increased growth rate and controlled crystal orientation of the titanium dioxide (TiO2) nanotubes could significantly enhance their efficiency in photocatalytic and photovoltaic devices. This presents a powerful approach for improving light absorption and charge transport in solar cells.

-

Microreactors and Catalytic Devices: The flow-regulated microfluidic anodization method is particularly suited for creating highly efficient TiO2-based microreactors for photocatalytic applications. The ability to control the growth and distribution of nanotubes within a microchannel allows for the optimization of surface area and flow dynamics for various chemical reactions.

-

Biomedical Applications: Uniformly structured nanotube arrays have potential uses in medical implants and drug delivery systems, where precise control over surface properties is essential for biocompatibility and function.

This invention provides a scalable and robust method for producing high-quality nanotubes with a level of control previously unattainable, offering a powerful platform for the development of innovative products across multiple industries.