US 11092391

ENHANCED BOILING WITH SELECTIVE PLACEMENT OF NUCLEATION SITES

Patent Number

Issue Date

Inventor(s)

Satish G. Kandlikar; Chinmay Patil

Document

Download PDF for patent US 11092391Synopsis

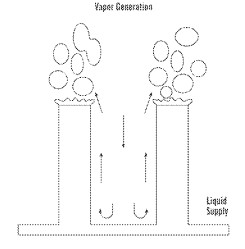

Patent US 11,092,391 B2 describes a system and method for enhancing boiling heat transfer through the selective placement of nucleation sites and the creation of specific re-entrant cavities. This invention aims to address the limitations of traditional boiling surfaces, which often suffer from inconsistent bubble detachment and liquid rewetting, leading to reduced heat transfer efficiency and potential for critical heat flux (CHF).

A key novel aspect of this patent is the deliberate design and arrangement of nucleation sites on a heat transfer surface. The invention proposes creating re-entrant cavities that not only facilitate the formation of vapor bubbles but also actively promote continuous liquid supply to the boiling surface and efficient bubble departure. These cavities are characterized by an opening that is smaller than the maximum cross-section of the cavity, which helps to trap vapor and stabilize nucleation. Crucially, the patent details the strategic spacing and arrangement of these re-entrant cavities, along with the creation of microchannels or pathways for liquid to flow into the cavities and for bubbles to depart. This combined approach ensures that the heat transfer surface remains continuously wetted, preventing the formation of insulating vapor films that lead to burnout or CHF.

The commercial potential of this invention is substantial in any industry that relies on efficient and reliable boiling heat transfer, particularly in applications where high heat fluxes must be managed within compact spaces. The ability to significantly enhance heat transfer coefficients and increase CHF can lead to more compact, energy-efficient, and durable thermal systems.

Possible applications include:

Electronics Cooling: With the escalating power density of electronic components (CPUs, GPUs, data center servers), effective heat dissipation is paramount. This technology could be integrated into liquid cooling solutions for high-performance computing, allowing for more compact and efficient removal of heat from critical components.

Power Generation: In steam generators, boilers, and other heat exchangers used in power plants (e.g., nuclear, thermal, geothermal), this enhanced boiling surface could lead to increased efficiency, reduced fuel consumption, and higher power output by improving steam generation rates.

Refrigeration and Air Conditioning: The improved boiling efficiency can enhance the performance of evaporators in refrigeration and air conditioning systems, leading to more energy-efficient cooling cycles and potentially smaller system footprints.

Renewable Energy Systems: In concentrated solar power (CSP) systems, efficient heat exchangers are vital for transferring solar thermal energy to working fluids. This technology could optimize the performance of receivers and boilers, enhancing overall system efficiency.

Chemical and Process Industries: Many industrial processes involve boiling or evaporation steps. This enhanced surface could improve reaction efficiency and product yields by optimizing heat management in reactors, reboilers, and evaporators, leading to reduced operational costs.

Waste Heat Recovery: The ability to efficiently transfer heat from various low-grade sources could be applied in systems designed to recover waste heat and convert it into useful energy, improving energy sustainability.

This patent offers a fundamental advancement in boiling heat transfer technology, providing a pathway to more efficient, compact, and high-performance thermal management solutions across a broad spectrum of industrial and technological applications.