US 11512390

Method of Site-Specific Deposition Onto a Free-Standing Carbon Article

Patent Number

Issue Date

Inventor(s)

Brian J. Landi, Cory D. Cres, Anthony P. Legiero

Document

Download PDF for patent US 11512390Synopsis

Patent US 11,512,390 B2 describes a method for site-specific deposition onto a free-standing carbon article, such as a carbon nanotube (CNT) article. The invention addresses the challenge of precisely depositing materials onto complex carbon structures, which is crucial for enhancing their electrical, thermal, and mechanical properties for various advanced applications.

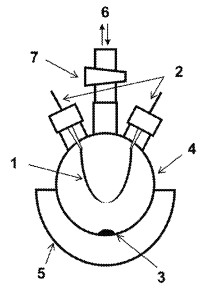

A key novel aspect of this patent is the ability to achieve site-specific deposition through a controlled chemical vapor deposition (CVD) process. The method involves suspending a free-standing carbon article within a reaction chamber, introducing a chemical precursor into the reaction environment, and then selectively heating the carbon article. This localized heating, often achieved by passing a current through the carbon article itself, causes the chemical precursor to decompose and deposit specifically onto the heated areas of the carbon article, rather than uniformly across its entire surface. This targeted deposition allows for the creation of hybrid materials with precisely engineered interfaces and properties. The patent highlights the use of an electrical bias to heat the carbon article, enabling a fine level of control over the deposition location and morphology.

The commercial potential of this invention is significant across a range of high-tech industries that utilize advanced carbon materials, particularly carbon nanotubes, for their superior properties. The ability to precisely functionalize these materials at specific sites can unlock new levels of performance and open up novel applications.

Possible applications include:

High-Performance Composites: Creating enhanced interfaces between carbon nanotubes and other materials (e.g., metals like copper) for lightweight, high-strength, and high-conductivity composites. These could be used in aerospace, automotive, and defense industries for structural components, wiring, and shielding.

Advanced Electronics and Interconnects: Improving the electrical conductivity and current-carrying capacity of carbon nanotube-based wires and interconnects. This is critical for next-generation microelectronics, flexible electronics, and high-frequency devices where efficient electron transport is paramount.

Energy Storage Devices: Developing more efficient electrodes for batteries and supercapacitors by depositing active materials onto specific sites of carbon nanotube scaffolds, leading to higher energy density, faster charging, and improved cycling stability.

Sensors and Actuators: Fabricating highly sensitive and selective sensors by depositing specific functional materials onto carbon nanotube structures at desired locations, enhancing their ability to detect chemicals, biological agents, or physical changes.

Thermal Management: Creating advanced thermal interface materials or heat sinks by depositing highly conductive materials onto carbon articles to improve heat dissipation in high-power electronic devices.

Catalysis: Designing more efficient catalysts by precisely placing catalytic nanoparticles onto specific active sites of carbon nanotube supports, which can enhance reaction rates and selectivity in various chemical processes.

This technology provides a versatile and controllable method for customizing the properties of free-standing carbon articles, offering a pathway to developing next-generation materials and devices with unprecedented performance characteristics.