12,088,008

Laser Cut Carbon-Based Reflector and Antenna System

Patent Number

Issue Date

Inventor(s)

Ivan Puchades; Brian Landi; Ian D. Peterson; Rodney S. Sorrell; Stephen R. Landers; Andrew Bucossi

Licensed/Under Negotiation

Document

Download PDF for patent 12,088,008Synopsis

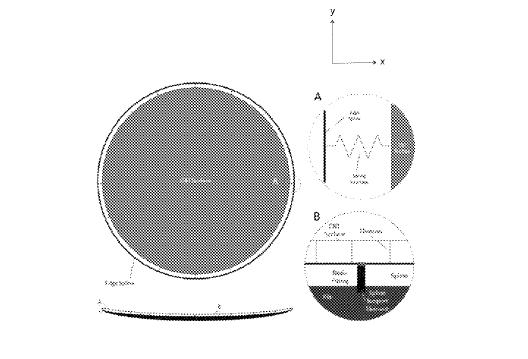

Patent US 12,088,008 B2 describes a novel electromagnetic reflector and antenna system, along with a method for its fabrication and use. This invention introduces a non-knitted, non-metallic carbon-based material mesh designed for superior radio frequency (RF) reflection and integration into various systems. The core innovation lies in leveraging laser-cut carbon nanotube (CNT) sheets to create highly efficient and versatile RF reflectors.

Novel Aspects and Advantages:

The key differentiating feature of this invention is the use of carbon nanotube (CNT) material, specifically in a non-knitted mesh form produced by laser cutting. Unlike traditional knitted metallic meshes, which can be prone to damage and offer limited design flexibility, this CNT-based reflector provides significant advantages:

- Exceptional RF Reflectance: The CNT mesh exhibits high RF reflectance, maintaining nearly 100% reflectance for frequencies below 30 GHz and remaining above 95% up to 50 GHz. This consistent performance across a broad frequency range (X to Ka-band) makes it highly effective for various communication and sensing applications. The reflective properties are achieved when the mesh opening size is less than 1/10th of the wavelength of the RF signal.

- Lightweight and Durable: Carbon nanotubes are known for their strength and low density, resulting in an exceptionally lightweight reflector. This material also offers improved durability, resistance to environmental factors like temperature and humidity, and is less susceptible to damage compared to traditional wire meshes.

- Flexibility and Foldability: The non-metallic CNT mesh is inherently flexible and can be designed to be foldable and deployable. This characteristic allows for compact storage and rapid deployment, a critical feature for many modern applications.

- Precision Fabrication via Laser Cutting: The use of laser cutting enables precise patterning and customization of the mesh with very small opening sizes (e.g., 100 microns or 200 microns). This manufacturing technique allows for the creation of intricate shapes and patterns, including those for parabolic or spherical reflectors, with high accuracy and repeatability. This method can also be more cost-effective for complex designs than traditional manufacturing.

- Tunable Optical Transmission: A significant breakthrough, the reflector boasts tunable optical transmission. This unique feature allows the mesh to be transparent or opaque to visible light while maintaining its RF reflective properties, opening up new possibilities for integration and aesthetics.

- Integration and Structural Stability: The CNT surface can be integrated with a backing structure frame and support elements (like splines and ribs) to achieve desired curvatures and maintain structural integrity, particularly for shaped reflectors. This design allows for controlled deformation and precise RF performance.

Commercial Potential and Applications:

The novel attributes of this laser-cut carbon-based reflector present a compelling opportunity for licensing across several high-growth industries:

- Deployable Satellite and Portable Communication Systems: The lightweight, flexible, and foldable nature of the reflector makes it ideal for deployable antennas in space applications, such as CubeSats or large communication satellites where compact storage and reliable deployment are crucial. It is also highly suitable for portable and rapid-deployment ground-based communication systems used in disaster relief, military operations, or remote broadcasting.

- Next-Generation Wireless Infrastructure: As wireless communication moves into higher frequency bands (e.g., 5G, 6G, and beyond), efficient and compact antenna solutions are essential. This technology could enable more discreet and integrated antenna arrays for urban environments or for enhancing connectivity in challenging terrains.

- Radar and Sensing Systems: The high RF reflectance and broad frequency performance make it valuable for advanced radar systems, including those used in autonomous vehicles, drone detection, and weather monitoring. Its lightweight nature could reduce the overall weight and power requirements of such systems.

- Unmanned Aerial Vehicles (UAVs) and Aerospace: The combination of low weight, high strength, and RF performance is highly attractive for UAV communication and sensing payloads, improving flight duration and operational capabilities. It could also find application in other aerospace components requiring both structural integrity and RF functionality.

- Concealed and Multi-Functional Integration: The tunable optical transmission offers a unique advantage for applications where an antenna needs to be optically transparent or integrated seamlessly into a structure without being visually obtrusive. This could include smart windows, building facades, or vehicle body panels that also function as communication or sensing elements, enabling a new class of multi-functional materials.

- Consumer Electronics: As connectivity expands, compact and high-performance antennas are increasingly needed in various consumer devices. The scalability and precision of laser cutting could enable customized antenna solutions for a range of products.

This technology offers a superior alternative to traditional metallic mesh reflectors, addressing critical needs for lighter, more durable, higher-performing, and more adaptable RF solutions. The ability to precisely tailor the material via laser cutting and its inherent flexibility and durability pave the way for widespread adoption across a variety of demanding applications.