Simulation tools are now available to simulate complex gear measurements after heat-treatment simulation. This is the focus of the feature article that has just been published in Thermal Processing, and that is available online here.

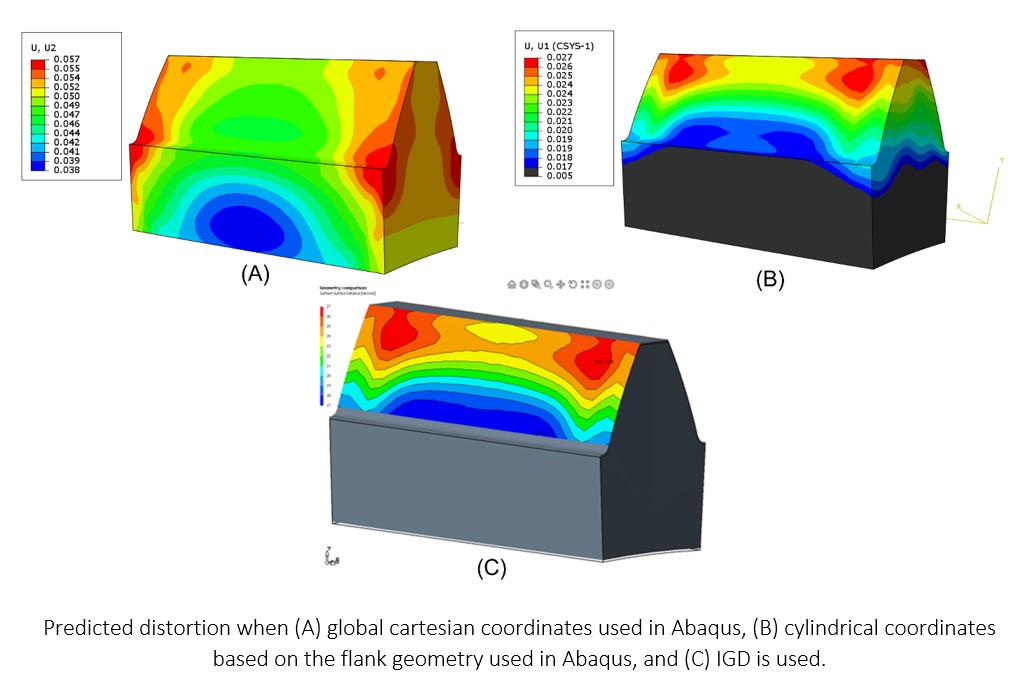

Heat treatment simulation provides a cheaper and faster alternative to physical testing but is lacking the capabilities to relate the predicted distortion back to gear measurements made on the shop floor or in the metallurgical lab. In general, diameter distortion predictions are easily understood and correlated back to actual measurements, but simulated predictions on parameters such as tooth thickness, tooth profile, and runout can be more daunting to evaluate and are often ignored in published analyses. To bridge this gap, two software programs can be used to provide common gear measurements on the simulated, heat-treated gear. IGD - Integrated Gear Design - developed at the Rochester Institute of Technology, is used to design the gear geometry and post-process the heat-treatment simulation results. DANTE, developed by DANTE Solutions, is used to simulate the heat treatment of steel components.

IGD provides tools for gear analysis and simulation, including, but not limited to, tooth contact analysis (TCA), finite element modeling of gear drives (FEM), and gear geometry comparison. An important feature of IGD is the automatic generation of finite-element models for ABAQUS or ANSYS, allowing finite-element analyses of complex gear drives without the tedious process of building the finite-element model or being an expert on the particular finite-element software being used. IGD takes advantage of geometric parameters commonly used in industry to construct the virtual gear geometry, including tip and root diameters, form diameters, circular tooth thickness, ball/pin diameter, and distance over balls/pins. Then, the FE models can be exported for heat-treatment simulation using DANTE, and the distorted gear geometry after heat-treatment simulation imported back into IGD for further inspection and measurements.

Read more at: https://thermalprocessing.com/gear-inspection-methods-from-heat-treat-simulation/