Development of a Custom-Made Low-cost 3D Bio-printer

This exhibit presents the innovative transformation of a traditional $170 3D printer into a versatile bioprinter capable of fabricating complex biological structures. The project focuses on adapting affordable consumer-grade technology to enable precise control over biofabrication processes. The main objective of this custom-made bioprinter development is to allow printing biological structures with tissue-specific porosity facilitating the tailored mechanical properties. A specialized nozzle-holding device has been meticulously designed and tested to accommodate a protective barrier, ensuring the integrity of a wide range of biomaterials developed in-house. The future intention is to release biomaterial mixed with living cells. Through a combination of hardware modification and software optimization, this bioprinter offers researchers and enthusiasts a start-point with a cost-effective solution for exploring biofabrication techniques. This exhibit showcases the ingenuity of leveraging existing technology to democratize access to advanced biofabrication tools, fostering innovation and collaboration in the field of biotechnology. This study not only advances bioprinting technology but also highlights the pivotal role of innovative engineering in overcoming tissue engineering challenges. The proposed bioprinter design establishes a promising foundation for further research, aiming for more accurate, efficient, and secure bioprinting solutions. Visitors will gain insight into the potential of low-cost 3D printing platforms to drive progress in biomedical research and accelerate the development of personalized medical treatments.

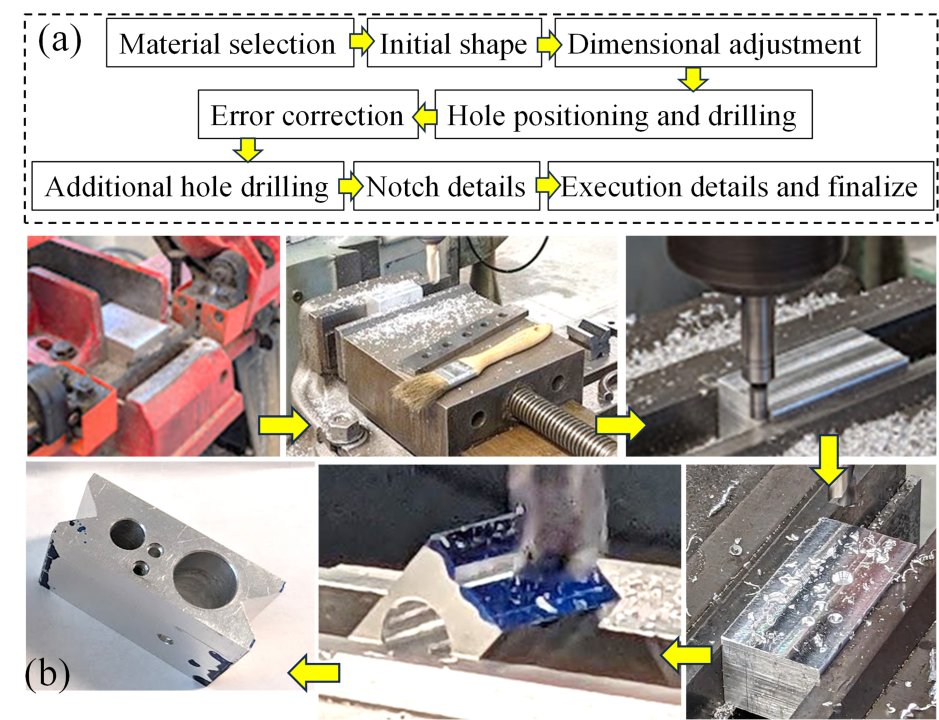

(a) The flow of plan to fabricate the cartridge holder using aluminum and (b) Fabrication steps from initial shaping using drop bandsaw to manufacture it to the specified dimension using Bridgeport.

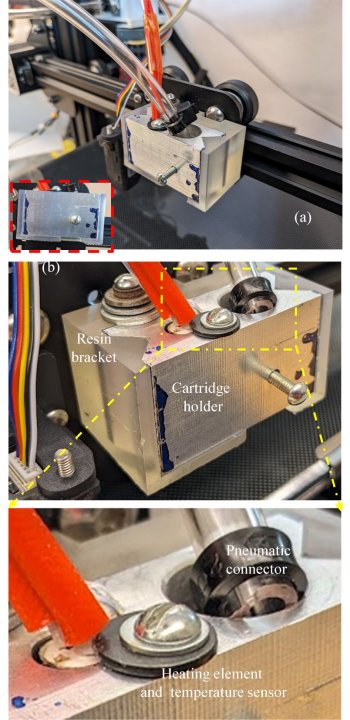

Aluminum cartridge holder and resin bracket assembly along with pneumatic connector and heating element and temperature sensor.

(a) All components used to build air control systems and (b) assembled air control systems.

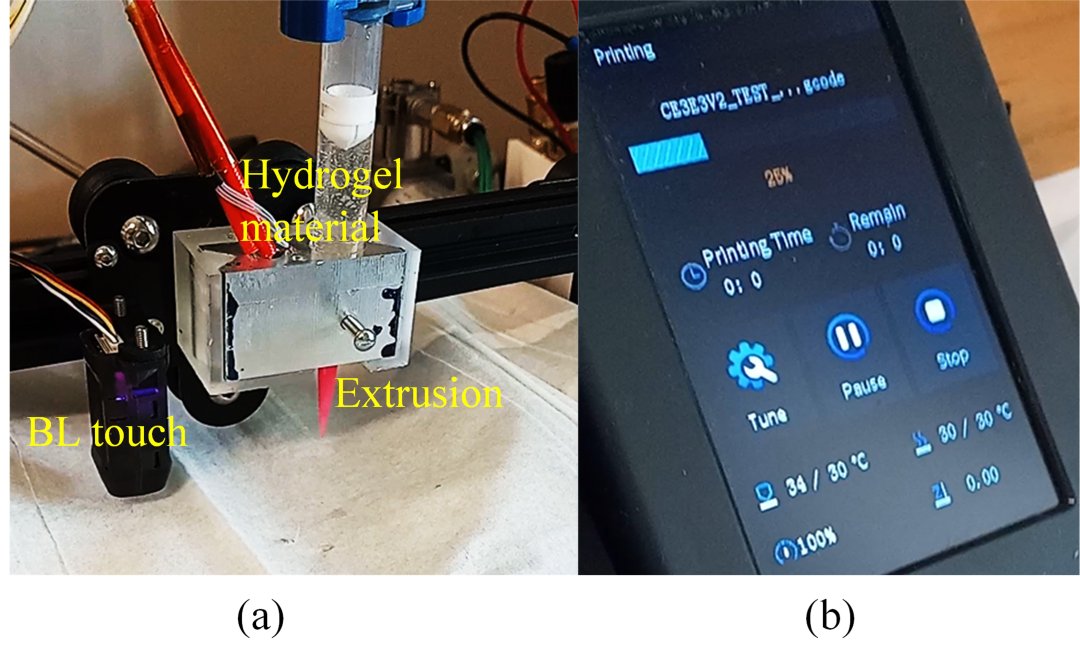

(a) Nozzle holder attached to the Ender 3 printer and (b) working with our customized G-code.

Topics

Exhibitor

MD AHASAN HABIB

Sean Pacilio

Perrin Woods

Advisor(s)

My research student Perrin Woods and Sean Pacilio will present this.

Organization

Manufacturing and Mechanical Engineering

Thank you to all of our sponsors!