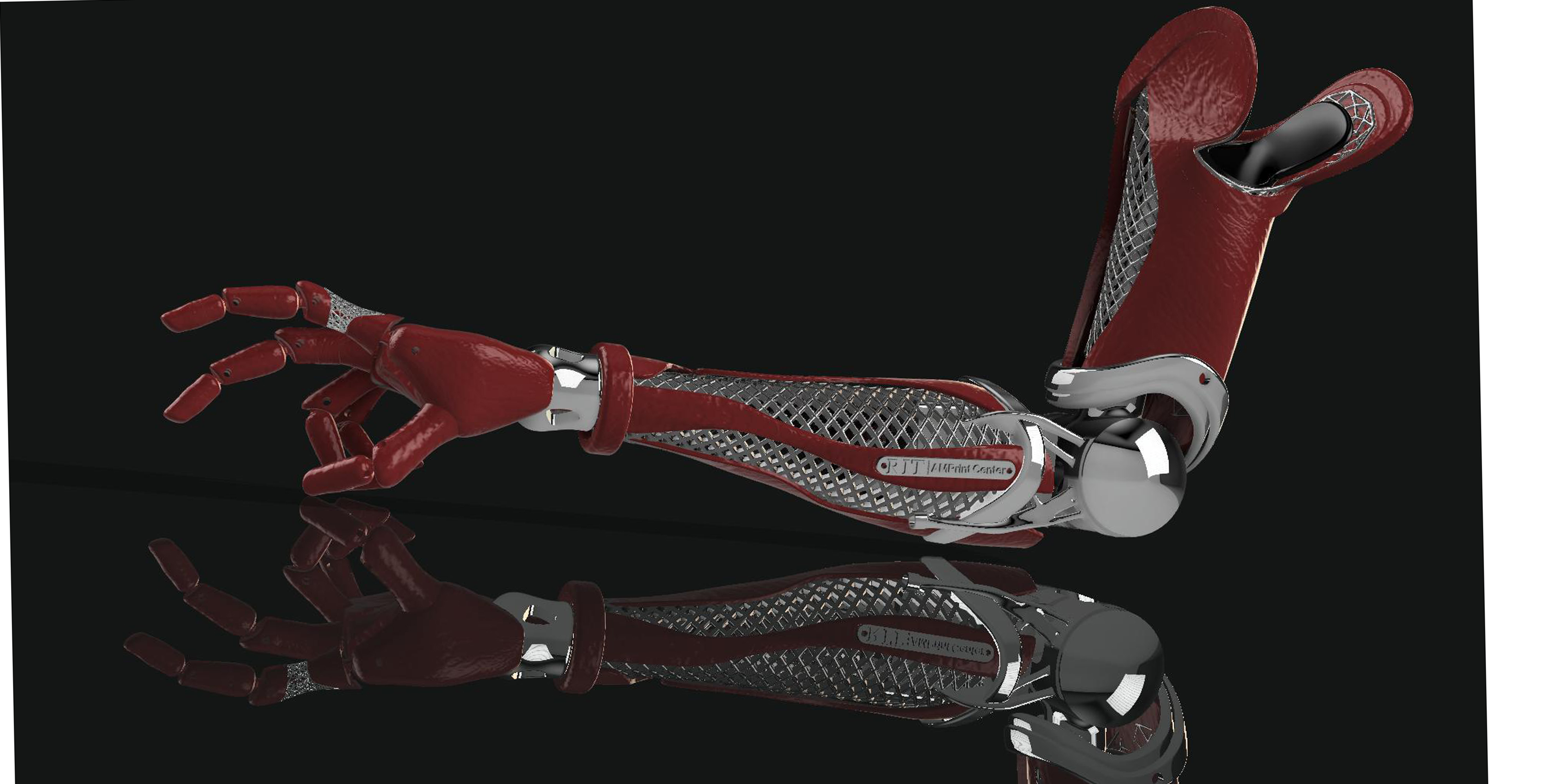

Jade Myers: Improving Prosthetic Design

Jade holds positions as a Research Development Specialist within the AMPrint Center and as Adjunct Faculty within the Kate Gleason College of Engineering at RIT. She has Ph.D. in Mechanical and Industrial Engineering and has instructed and co-instructed several courses, including Medical Device Design, 3D-Technologies for Prosthetic Applications, and Personalized 3D Printing. She has served as the Haiti Project Team Lead for a non-profit specializing in increasing access to quality upper limb prostheses for underserved communities and has collaborated on multiple international low-cost medical device projects involving 3D printing. Her current research centers on finding innovative ways to improve the design and safety of printed upper limb prosthetic sockets—the critical interface between a person and their prosthetic device.

“We apply a novel method for providing strategic areas of compression and release within a cushioned prosthetic socket using lattice structures of varying densities.” This lattice cushioning is printed using a flexible polymer. It offers the necessary support on either side of the residual bone to stabilize the prosthesis and allow for a more direct translation of user-provided energy to the intended movement of the prosthetic device. At the same time, the gradual change in lattice density between areas of compression and release can help decrease the risk of tissue damage that can be caused by pressure and shear when too abrupt of a transition is made in compressibility over a short distance.

Additive technologies make patient-specific customization possible. Using these technologies, we aim to improve the performance and safety of low-cost prostheses for people who might benefit from them anywhere in the world.