Center for Remanufacturing and Resource Recovery

Center for

Remanufacturing and Resource Recovery

- RIT/

- Golisano Institute for Sustainability/

- Center for Remanufacturing and Resource Recovery

We’re the world’s leading research center dedicated to the advancement of remanufacturing.

At the Center for Remanufacturing and Resource Recovery (C3R®), we’re meeting the biggest challenges facing the remanufacturing industry. Our team of researchers, engineers, and experts combine the power of innovative research with practical industrial experience to develop new technologies that will grow remanufacturing’s potential for businesses.

We leverage our expertise through impactful thought leadership to nurture a better economic environment for remanufacturing at the national and global levels. Our research—supported by partnerships with leading organizations like the United Nations, Remanufacturing Industry Council, Caterpillar, and The REMADE Institute—seeks new knowledge, tools, methods, and approaches to innovate and expand the remanufacturing industry.

A Pathway to a Circular Economy

As a sustainable form of industrial production, remanufacturing is a pillar of what is known as a circular economy. Our current economy—everything we make, sell, buy, and use—accounts for the bulk of greenhouse gas (GHG) emissions going into our air. More than half of those emissions are released during the extraction and processing of raw materials and the manufacturing of goods. Only about 9% of the 92.8 billion tons of minerals, fossil fuels, metals, and biomass that enter the economy each year are re-used in any way.

A circular economy aims to reverse these trends through three basic principles: Design waste and pollution out of our economic system, keep products and materials in use, and regenerate natural systems. Its goal is to shift from today’s linear economic model—which begins at an oil well, a coal mine, or a mineral quarry—to one where industrial production is decoupled entirely from the consumption of the earth’s finite resources. Remanufacturing plays a critical role in this strategy because it enables companies to extend the life of products and components into many usage cycles while capturing maximum value from materials, labor, and energy.

Research and Technologies

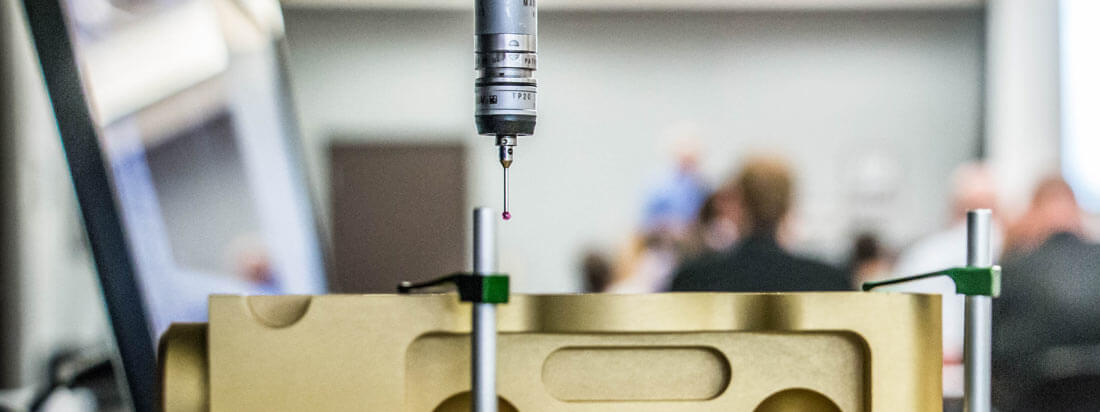

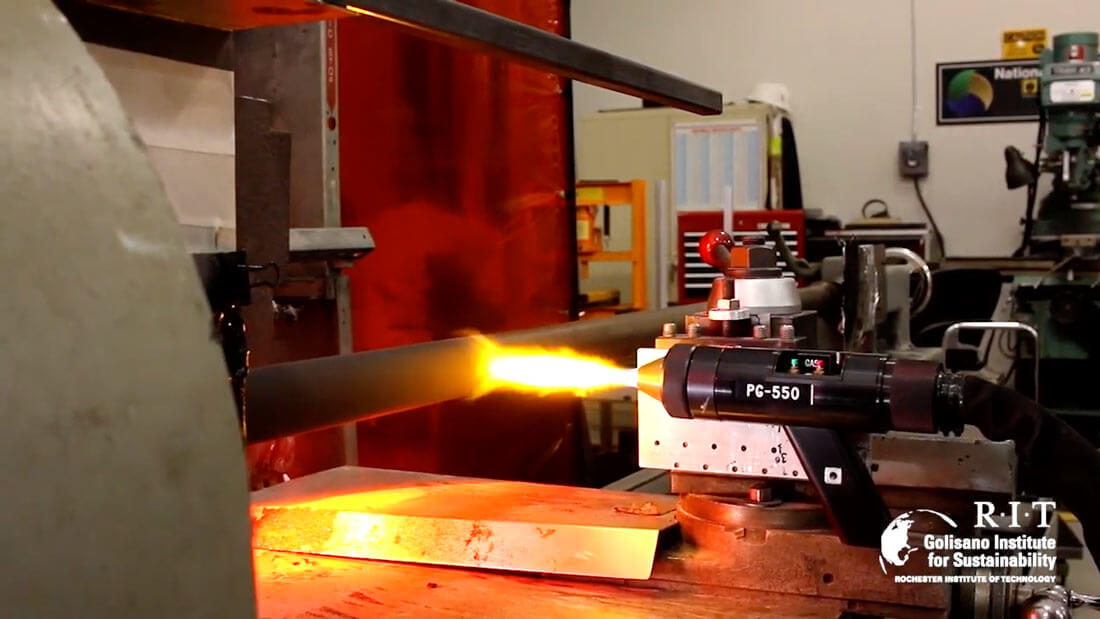

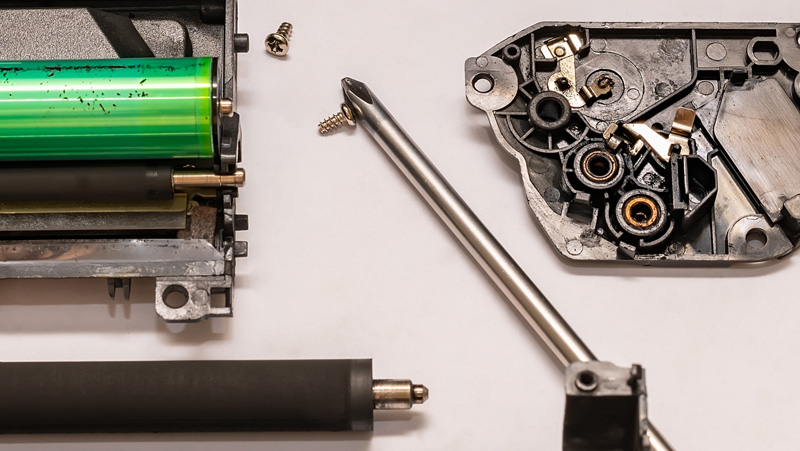

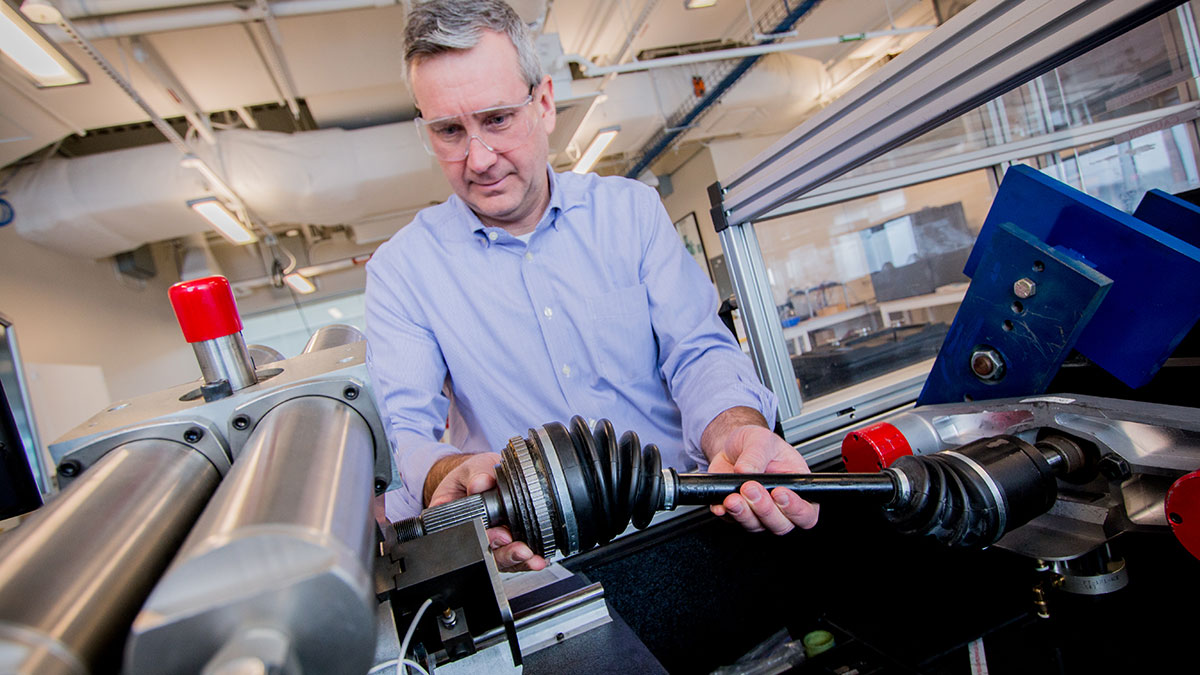

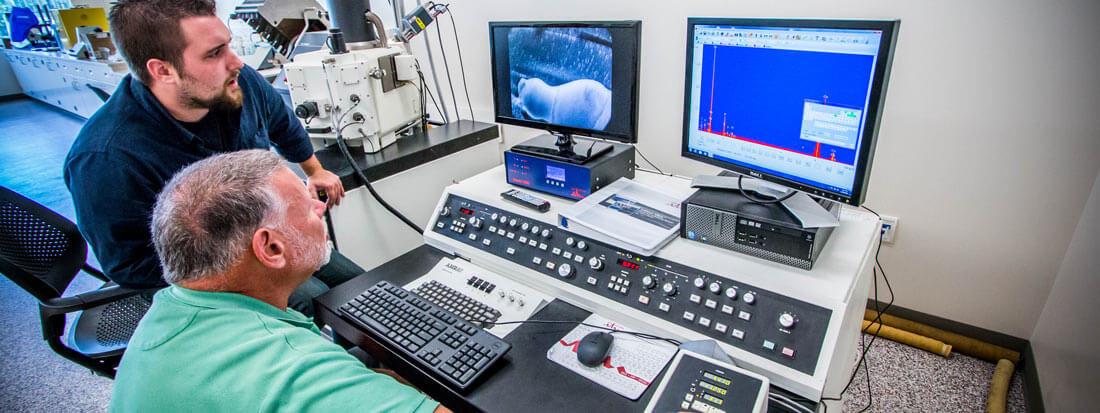

The C3R® program is driving remanufacturing and resource recovery innovation. As an international leader, the C3R® team supports industry, NGOs, and policymakers as a trusted resource for remanufacturing research, evaluation, engineering, and technology development. Additionally, our one-of-a-kind remanufacturing testbed offers advanced facilities, equipment, and technologies capable of furthering key remanufacturing areas, such as core identification, condition assessment, commercial cleaning processes, and additive repair.

Partnerships and Projects

The C3R® team is involved in major endeavors worldwide to help move the remanufacturing industry forward. We consistently work with industry, government agencies, and other universities on projects that will help remanufacturers improve their processes and knowledge.

Remanufacturing Technology Roadmap: In 2017, we published a report identifying research priorities that would improve remanufacturers’ capabilities and competitiveness of U.S.-based firms. The report was used to build consensus around barriers to competitiveness and research priorities.

UN Partnership: The director of our institute, Dr. Nabil Nasr, is a member of the UN Environment Program’s International Resource Panel (IRP), which consists of eminent scientists, highly skilled in resource management issues. Their reports distill the latest scientific, technical and socio-economic findings around global resource use and solutions, including remanufacturing. A recent IRP report, authored by GIS researchers, made the case for remanufacturing by highlighting processes that retain the value of the products through extension of their useful life, contributing to a positive Circular Economy shift.

The REMADE Institute: We were selected through a highly competitive process to lead the creation and development of the U.S. Department of Energy’s 14th Manufacturing USA Institute called “The REMADE Institute.” Today, the institute operates as a national R&D consortium of leading universities and companies undertaking collaborative research and workforce development to mature promising recycling, reuse, and remanufacturing technologies.

Workshops and Training

C3R® services include our education program, RemanU®, which offers a wide variety of workshops and webinars to encourage resource recovery through the adoption of remanufacturing and to build a workforce with a skillset ready for a modern remanufacturing operation. Workshops can be customized to an organization’s unique needs and many can be delivered in a hands-on training format in our Remanufacturing Testbed that provides a real-world experience for trainees and immediate benefits to remanufacturers.

C3R® training also includes several short courses available through The REMADE Institute:

Introduction to Remanufacturing* - This short course offers a broad introduction to remanufacturing and end of life reuse process, related technologies, environmental impacts, and areas for growth. Discussions focus on economic models for remanufacturing, technologies utilized within remanufacturing, and how Industry 4.0 can be used to increase remanufacturing.

Cleaning Technology for Remanufacturing* - This short course builds on the cleaning technology principles spotlighted in the Introduction to Remanufacturing short course. Topics covered provide an overview and training on cleaning technology for remanufacturers. Discussions focus on how each technology areas fits within the remanufacturing process and why it is critical to successful remanufacturing.

Additive Repair Technology for Remanufacturing* - This short course builds on the additive repair principles spotlighted in Introduction to Remanufacturing. Topics covered will provide an overview and training on additive repair technologies. Discussions focus on how each technology areas fits within the remanufacturing process and why it is critical to successful remanufacturing.

Condition Assessment Technology for Remanufacturing* - This short course builds on the condition assessment principles spotlighted in the Introduction to Remanufacturing. Topics covered provide an overview and training on condition assessment technology for remanufacturers. Discussions focus on how each technology areas fits within the remanufacturing process and why it is critical to successful remanufacturing.

*REMADE membership is required for these courses. To view these and other courses, visit https://remadeinstitute.org/ewd/course-catalog/

Outreach

In addition to customized trainings, we work to actively educate those in the industry through regular events and offerings, including conferences, tours, open discussions, and other events. We also have several industry experts who could be available to speak at your event.

Annual RIC-RIT World Remanufacturing Conference: We host an annual conference centered around remanufacturing innovation, where we gather premier industry experts for two days of discussion and education around the future of remanufacturing.

Remanufacturing Testbed and Facilities Tours: We offer tours of our state-of-the-art remanufacturing facilities or those of our partners to educate engineers on the latest equipment and processes to the industry.

Reman Day: A global initiative, Reman Day is an annual collection of educational events, webinars, and workforce development initiatives, of which we help sponsor and support.

Featured Projects

Remanufacturing Delivers Savings for U.S. Marines

U.S. Marine Corps

Case for Remanufacturing Made to the U.N.

United Nations

What People Say About Us

“RIT’s vast network and collaborations is without peer. With a unique ability to bridge partnerships between global industrial leaders and SMEs, RIT helps advance remanufacturing as both a profitable and sustainable business strategy.”

John Disharoon

Director of Market Access, Caterpillar Inc

“RIT has been a tremendous resource in helping us stay competitive through industry best practice sharing and technical evaluations of emerging innovations. Its work over the years has created a strong foundation for better understanding industry needs and key stakeholders.”

Bill Davies

President, Davies Office