Industry 4.0 Academy

Industry 4.0 Academy

- RIT/

- Center of Excellence in Advanced and Sustainable Manufacturing/

- Industry 4.0/

- Industry 4.0 Academy

Industry 4.0 is revolutionizing manufacturing by integrating Internet of Things, cloud computing, analytics, AI, and machine learning into manufacturing and its supporting operations.

Smart factories use advanced sensors, software, and robotics to collect and analyze data, enabling better decision-making. By merging production data with information from other systems, such as MES, new levels of visibility and insights are achieved.

We can help you with learning materials to aid implementation of Industry 4.0

Overview

This website offers a curated collection of learning materials encompassing an Industry 4.0 overview, its benefits, adoption strategies, necessary skills, and strategies to maximize post-implementation benefits.

Numerous online resources are available for Industry 4.0 and associated methodologies. We have selected some to help you begin your journey. The topics covered cater to different organizational roles, skill levels, and maturity levels of Industry 4.0. The learning materials encompass articles, YouTube videos, online courses, web resources, and in-person training. Offerings are delivered by learning organizations, schools (including Rochester Institute of Technology), individuals, or companies.

Some of the learning materials are free, while others require a fee. No compensation has been provided to RIT by these other organizations. RIT is providing this information to support adoption of I4.0 technologies and practices. RIT’s work is supported by funding from the NYS Department of Economic Development.

If you have other learning materials you found beneficial, please provide us feedback so we can share with others. If you are still looking for more topics not found here, let us know that too!

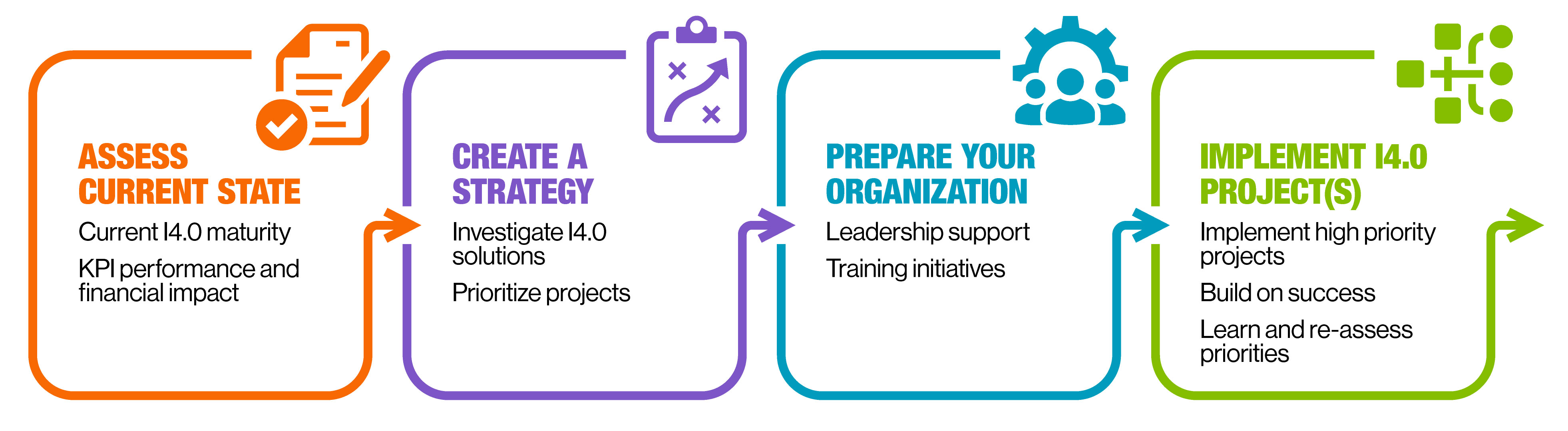

Implementation Roadmap

Implementing Industry 4.0 successfully can be a challenging task. First start with assessing your current state to understand opportunities, create a strategy, get your organization ready for I4.0, and finally begin implementation of I4.0 targeting the high priority projects. For more information on assessments or implementation refer to the Course Catalog Getting Started or Contact Us. Additional assessment information is available at “The Smart Industry Readiness Index” from the International Centre for Industrial Transformation.

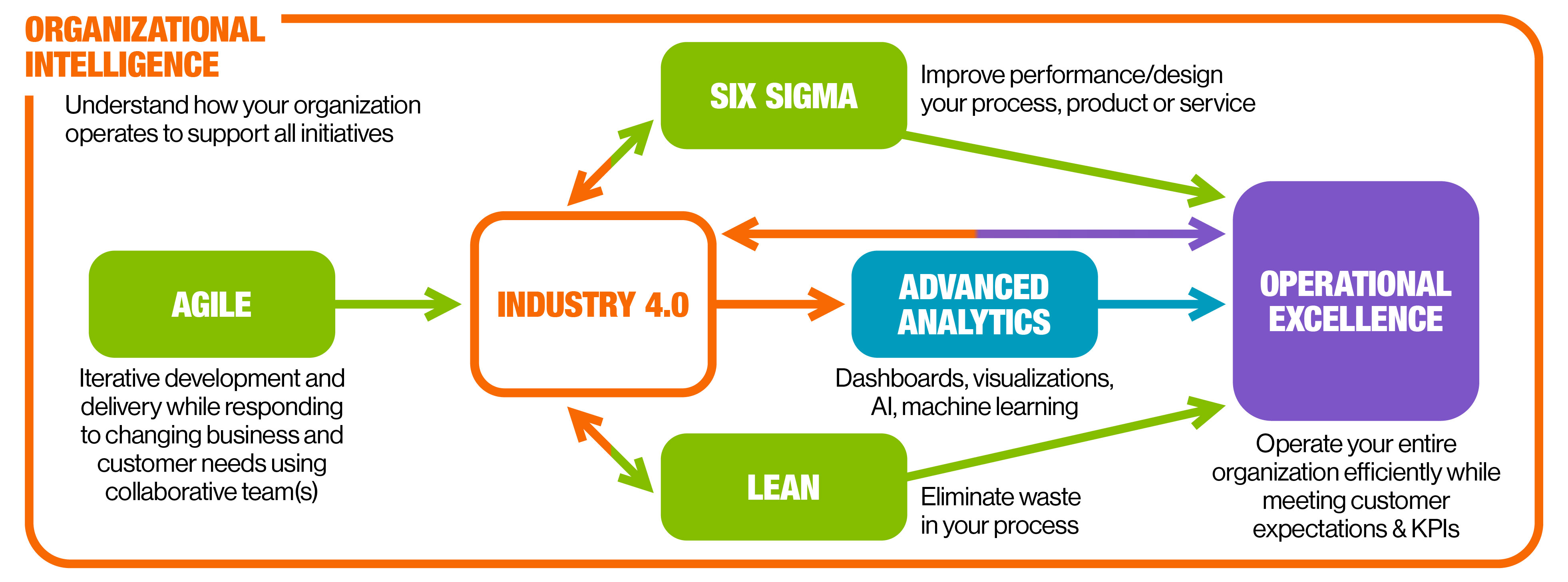

Related Industry 4.0 Methodologies

To maximize the benefits of Industry 4.0, it is important to integrate with relevant methodologies. A key strategy is to prioritize the implementation of Industry 4.0 projects in the most critical areas and leverage the generated data to effectively address operational goals and problem-solving. Operational Excellence, Lean, and Six Sigma can assist in identifying the priority problem areas. Agile methodologies offer a systematic and iterative approach to implementing Industry 4.0, allowing for flexibility and adaptation to evolving business requirements.

Upon completion of Industry 4.0 project(s), the data becomes a valuable asset for enhancing processes and quality through Six Sigma, reducing cycle time and waste through Lean practices, gaining deeper insights into process metrics and performance via Advanced Analytics, and ultimately achieving organizational KPIs through Operational Excellence. A comprehensive understanding of your organization's operations, referred to as Organizational Intelligence, is instrumental in ensuring the success of each methodology.

To achieve a successful implementation of Industry 4.0, full leadership support for I4.0 projects and training is necessary.

General Industry 4.0

Industry 4.0 refers to the fourth industrial revolution characterized by the integration of advanced technologies, such as IoT, AI, and automation, into manufacturing and production processes to create smart, interconnected, and efficient systems.

Industrial Internet of Things (IIoT)

Integration of internet-connected devices, sensors, and systems in industrial environments to enable data collection, analysis, and automation, leading to enhanced operational efficiency and productivity.

Industrial Internet of Things (IIoT) Overview

Connectivity

SCADA

Sensors

Smart Sensors

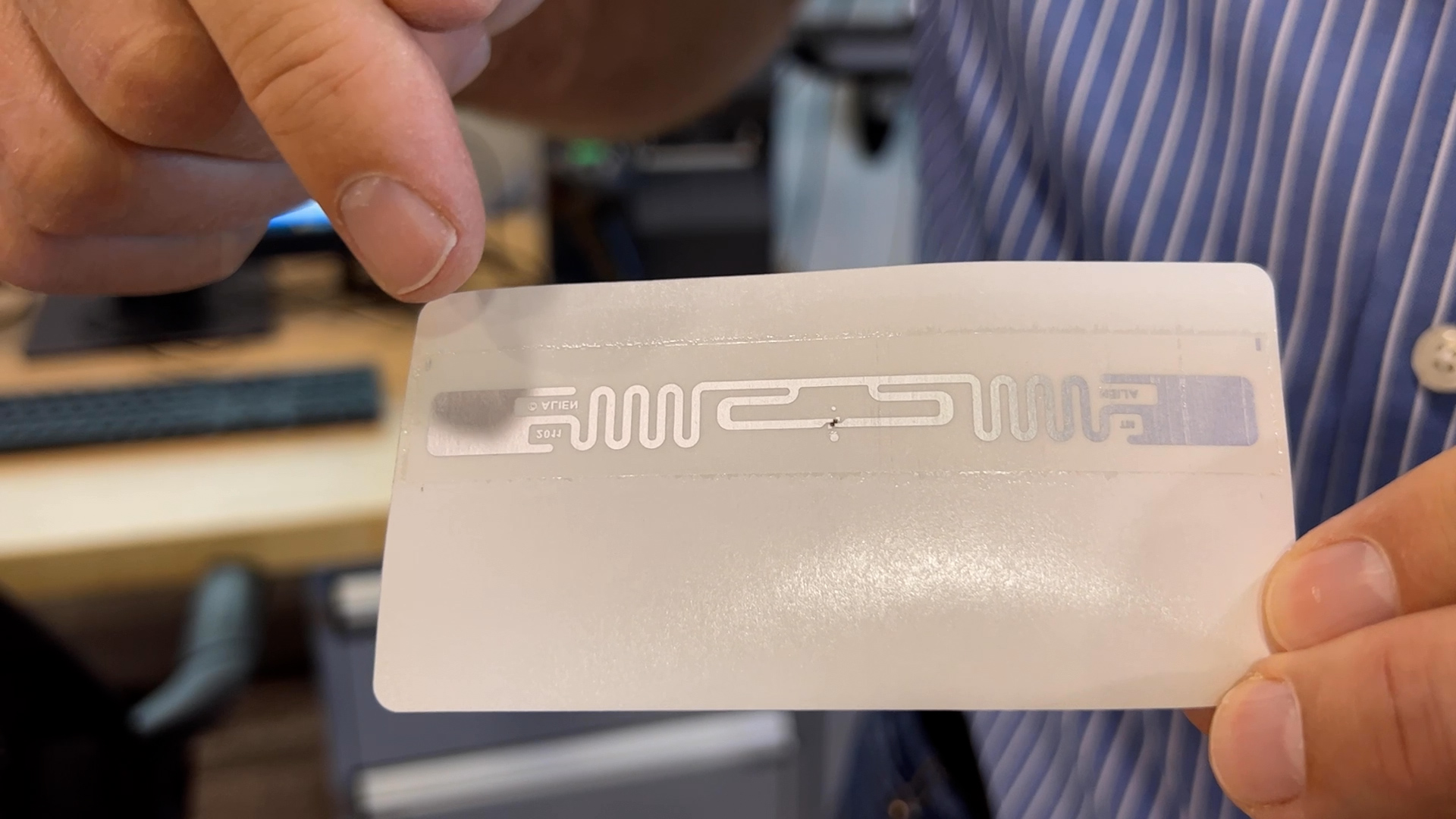

RFID/BT/Cell Tags

Automation

Used all across the shop floor and supporting business processes to save labor costs and streamline operations, from shop-floor routines to decision-making at the enterprise level.

Automation Overview

Additive Mfg/3D Print

Augmented Reality & Virtual Reality

Machine Vision

Predictive Maintenance

Robotics

Robotic Process Automation

Software & Systems

Used all across the shop floor and supporting business processes, vital to Industry 4.0 implementation.

Data Storage

Machine Monitoring

Network Security

Process Monitoring

Software Applications

Advanced Analytics

Sophisticated techniques and tools used to extract valuable insights and patterns from complex data sets, enabling informed decision-making.

Analytics Overview

Business Intelligence & Dashboards

Data Science

Foundations (Statistics & Excel)

Machine Learning/AI

Related Methodologies

Other methodologies used in combination with Industry 4.0 support and further enable benefit.

Agile

Lean / Six Sigma

Operational Excellence

Organizational Intelligence

Other

Industry 4.0 Overview Short Video Series

To help you get an introductory understanding of Industry 4.0 through demonstrations, a set of short videos were created by RIT’s Golisano Institute for Sustainability. Each video is less than 5 minutes. Topics include Industrial Internet of Things (IIoT), Part Tracking Systems like RFID, Vision Systems for part identifications using meshing vision and machine learning, Robotics, and Dashboards using Grafana for real-time monitoring. The videos were created by Golisano Institute's technical staff.

Elements of Smart Manufacturing Webinar Series

To gain a deeper understanding of Industry 4.0, the “Elements of Smart Manufacturing Webinar Series” was hosted by RIT’s Golisano Institute for Sustainability. The series provides in-depth discussions on various topics: software, human aspects, analytics, IIoT, and automation. Discussions were led by Rochester Institute of Technology Industry 4.0 Faculty/Staff and New York State Finger Lakes’ regional experts.

This information is being provided by Rochester Institute of Technology with funding provided by the NYS Department of Economic Development. Any statements, findings, and conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of the NYS Department of Economic Development.

I4.0 Academy Disclaimer

Industry 4.0 Academy Disclaimer

The courses offered in the catalog are a curated collection of learning materials that provide an overview of Industry 4.0. It is designed to provide resources that businesses can use to understand and implement Industry 4.0, covering topics such as technology adoption, data utilization, and workforce development. While some of the course providers may provide a certification, the intent of this website is to provide information on knowledge-building opportunities. RIT provides no certification or degree credit for any of this content.

Some materials are free, while others require a fee. Neither RIT or the Center of Excellence in Advanced and Sustainable Manufacturing (COE-ASM) has received compensation from the organizations that have created and published the course materials. The Industry 4.0 Academy supports a COE-ASM initiative to advance the adoption of Industry 4.0 technologies and practices among manufacturers in New York State and is funded by the New York State Department of Economic Development.