Home Page

Putting technology and innovation to work for the printing industry

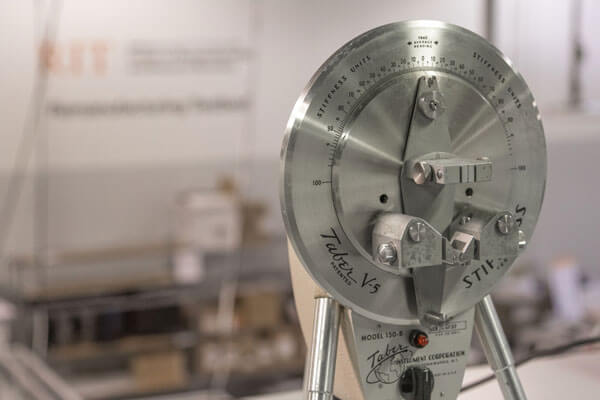

For over 70 years, RIT has been a center of printing technology innovation and education. Located in the imaging capital of the world, Rochester, New York, the Printing Applications Lab (PAL) in RIT’s Golisano Institute for Sustainability (GIS) is a valued partner for the global printing industry, providing a range of research and independent evaluation services.