About Battery Development Center Testing

Battery Testing

- RIT/

- Battery Development Center/

- Testing/

- About Battery Development Center Testing

At the BDC-Testing Center in Rochester, N.Y., batteries and energy storage systems are tested for performance, durability, and safety in a modern 18,000+ square foot facility.

The test center is an accredited ISO-17025 laboratory that provides independent test and validation services vital for cell and material developers, battery manufacturers, energy system integrators, project developers, and finance companies.

Over the 10 years since its inception, the BDC-Test Center has logged more than 7.5 million testing hours and has worked with over 100 companies. The test results are often used in due diligence reports and comparison studies to validate manufacturer cycle-life, performance, and warranty claims.

History

Since April 2024, the BEST Test and Commercialization Center (BTCC) is part of the Rochester Institute of Technology (RIT)-Battery Development Center (BDC), complementing the well-known cell prototyping capabilities of RIT’s Battery Prototyping Center. The test center was established in 2014 by the New York Battery and Energy Storage Technology Consortium (NY-BEST) and operated by DNV before its transition to RIT.

Cell Types and Chemistries

We test all cell types and chemistries, including:

Cylindrical

- Usually 1-10 Ah

- Often include Current Interruption Device (CID) or passive fuse

- Metal enclosure with vents

- Sizes: 18650, 21700, 4680, etc.

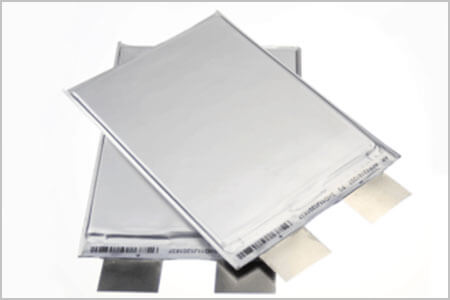

Pouch

- Usually 10-100 Ah

- Vacuum sealed

- Polymer skin with sealed edges

- CIDs less common

- Tested with compression plates

Prismatic

- Usually 50-350 Ah

- Vacuum sealed

- Aluminum can with polymer seals

- Typically include CIDs and vents

- Often tested with compression

Testing Focus Areas

The BDC-Test Center provides an extensive range of testing services covering performance and safety for batteries, controllers, and complete energy storage systems (ESS). Our experts test on a wide range of applications and scales, including batteries for large utility-scale energy storage systems, residential and commercial “behind-the-meter” applications (like residential storage systems and microgrids), electric vehicles (EVs), construction and material handling machines, as well as batteries for consumer goods and medical use.

State-of-the-Art Testing

Our ISO 17025-accredited Battery Development Center at RIT delivers precise, reliable testing for all battery types and chemistries, from small prototype cells to utility-scale systems. With over 7.5 million hours of testing experience, our labs feature specialized zones for optimized results.

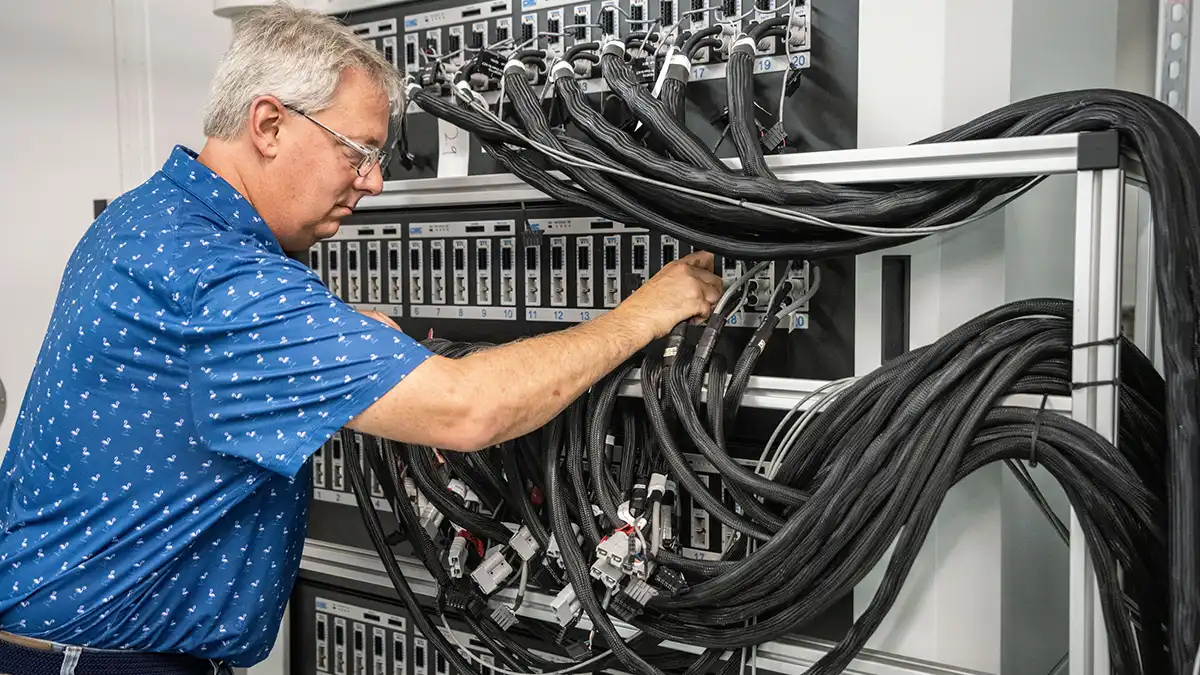

Performance and Life-Cycle Testing: Our facility features hundreds of high-capacity precision cycler channels (5V–1500V), EIS testing, and climate chambers for thorough performance and degradation testing of cells, modules, and packs, including thermal stability, BMS balancing, and failure response studies.

System Performance Testing: We evaluate integrated energy storage systems (e.g., residential and commercial ESS) across all operating conditions using advanced AC-grid, load, and PV-module simulators, climate chambers, and HALT/HASS reliability tests like humidity freeze and temperature cycling.

Safety and Abuse Testing: Offers cell-level burn and abuse tests (e.g., UL9540A, nail penetration, overheat, overcharge, short circuit) with gas collection and analysis, plus custom tests like thermal runaway propagation and state-of-health (SOH) for used batteries. A new facility is being added for module and pack-level safety testing.

We’re expanding our testing infrastructure with a new Safety & Burn Test Facility, boosting lab space, capacity, and capabilities to meet industry demands and support your battery validation and commercialization goals.