Research Brief: Advanced Biomanufacturing

Project Brief

Type of Research: Advanced Biomanufacturing

Motivation for Research: Autologous bone grafting is considered the gold standard for the functional and structural reconstruction of bone defects caused by trauma, infection, or congenital disorders. Despite its success, limitations such as donor site morbidity, the complexity of the surgery, limited supply of donor tissue, and the potential for donor site infection have created the need to develop alternative clinical techniques for comprehensive bone regeneration. Bone tissue engineering is a subset of regenerative medicine that aims to repair and regenerate damaged human tissues by using a combination of scaffolds, cells, and biological signals. Scaffolds are engineered biomaterial structures that act as templates for the formation of new tissue by encouraging the migration, interaction, and proliferation of living cells.

Research Approach

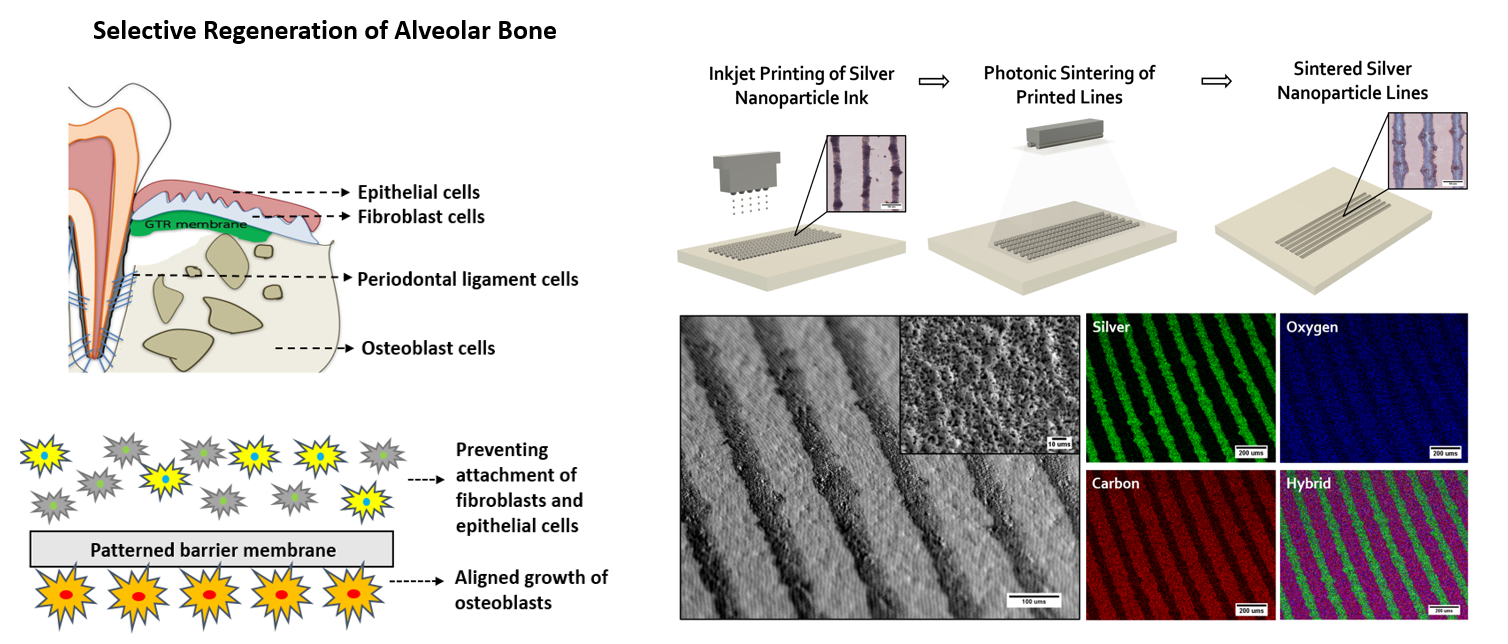

Scaffold-based bone regenerative treatments use surgically implanted biodegradable structures to induce, guide and mechanically support the regeneration of damaged tissues. Guided bone regeneration is a dental surgical technique that utilizes barrier membranes to direct and delineate regions of osteogenesis. An ideal barrier membrane must act as a physical blockade and prevent the invasion of periodontal defects by bone-inhibiting elements such as fibroblasts, epithelial cells, and bacteria. Since cells are innately receptive to nano and micro-scale topographical features, barrier membranes with engineered physical characteristics can orchestrate cell fate processes such as adhesion, migration, proliferation, and differentiation. In that regard, it may be beneficial to create barrier membranes with topographical features that can effectively exclude non-osteogenic cells and bacteria from interfering with bone regeneration. Sri’s dissertation proposes to leverage the flexibility of additive manufacturing to modify the surface topology of resorbable polymer membranes with a final objective of achieving comprehensive alveolar restoration. He is investigating a two-step strategy that involves the direct ink writing of silver and hydroxyapatite nanoparticles and the photonic sintering of the printed ink to generate adhesive and non-adhesive patterns on polymeric barrier membranes. Preliminary results confirm the capability of the approach to generate stable micron-sized groove/ridge patterns. Future studies will focus on exploring the mechanobiological response of various cell types (i.e., osteoblasts, fibroblasts, and epithelial cells) and the response of Staphylococcus aureus and Escherichia coli to the patterned membranes. The research team expects that the proposed novel strategy will hold promise for high throughput modification of barrier membranes for use in guided bone regeneration.

Key Benefits

Direct ink writing approaches such as inkjet or aerosol jet printing offer the benefit of creating bioactive surfaces that provide topographical and chemical cues to cells. Commercial printers can be modified to dispense biomolecules or cells onto substrates such as coverslips, implant surfaces, and biomaterial templates. It is also possible to deposit multiple layers of different materials, large volumes of material, and even gradients.

Looking Ahead

Sri is currently preparing to test the antibacterial efficacy of the micro-patterned barrier membranes. He expects to complete his experiments and defend his dissertation in the Summer of 2022. Apart from his doctoral dissertation work, Sri has published several journal articles that investigate novel strategies for improving clinical outcomes in scaffold-based tissue engineering.