RIT students earn second in e-waste design contest

Industrial design students Isaac Alves and Joseph Lapke win second place

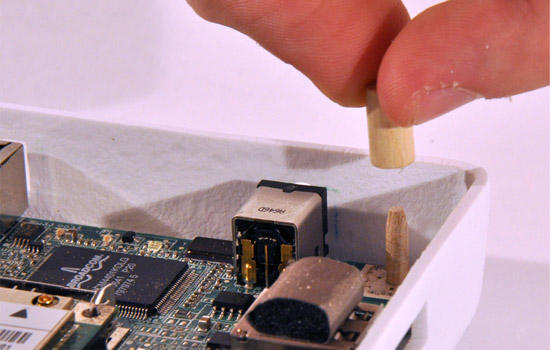

Industrial design students Isaac Alves and Joseph Lapke developed a laptop that can be fully disassembled in about 90 seconds. These are components of a laptop computer. The students did not alter the size and shape of the components.

Two industrial design students from Rochester Institute of Technology, Isaac Alves and Joseph Lapke, won second place in the 2011 International E-Waste Design Competition.

The team of fourth-year industrial design students developed a laptop that can be fully disassembled in about 90 seconds. Alves and Lapke’s project, called Dismantle, won gold honors in the prevention category of the competition and earned them $3,000 in prize money. The competition is part of the Sustainable Electronics Initiative at the University of Illinois at Urbana-Champaign.

College students and recent graduates from around the world submitted their ideas for products or services to prevent electronic waste or e-waste generation (prevention category) or that incorporate e-waste components into a new and useful item (reuse category). Computers, TVs, cameras, printers and cell phones are generators of e-waste. Jurors awarded monetary prizes to the top three projects within each category, along with three honorable mention awards.

“It feels really good to have our work recognized not only at the national level, but at the international level, too,” says Lapke. “Earning this award is a true testament to our hard work and effort we put in every day as designers in the RIT industrial design program.”

For their design, Alves and Lapke replaced screws with “drafted embossed fasteners” and employed a “master lock” pin to hold the laptop’s circuit board in place, allowing for the computer to be disassembled in about 90 seconds. A Dell Inspiron 15-inch laptop takes about 12 minutes to disband.

“The short period of disassembly time is primarily due to the easy accessibility that we have created through adding drafted embossed fasteners to hold the interior components in place, and by eliminating all screw fasteners,” says Alves. “Therefore, by saving time in the disassembly process at a laptop’s ‘end-of-life,’ those performing the disassembly will be able to go through more units in a given time period with less tooling required, allowing them to be able to have more time to recover some of the precious metals and other materials from the laptop. Secondly, our implemented system will save the hassle and the need to manufacture many different types of screw fasteners to fit the laptop.”

Alves, of East Greenwich, R.I., and Lapke, of Southbury, Conn., both graduated from RIT in May. They came up with their concept in a sustainable product design course co-taught last fall by Alex Lobos, assistant professor of industrial design in RIT’s School of Design, and Callie Babbitt, assistant professor in RIT’s Golisano Institute for Sustainability. The class was comprised of industrial design undergraduate students and sustainability Ph.D. students.

A team of four industrial design students from RIT won first place in last year’s International E-Waste Design Competition, taking the top prize in the artist/designer category for their design of a cell phone that can disassemble. The phone included a generator component and a replaceable hardware cartridge.

Industrial design students Isaac Alves and Joseph Lapke implemented a new component in their laptop design, utilizing a pin/key that fits to an embossed fastener to allow for the computer to be disassembled in under two minutes.

Industrial design students Isaac Alves and Joseph Lapke implemented a new component in their laptop design, utilizing a pin/key that fits to an embossed fastener to allow for the computer to be disassembled in under two minutes.