Undergraduate students create sustainable packaging options for Milwaukee Tool

Coursework provides hands-on design experience for students and new packaging ideas for company

Jesse Wolfe

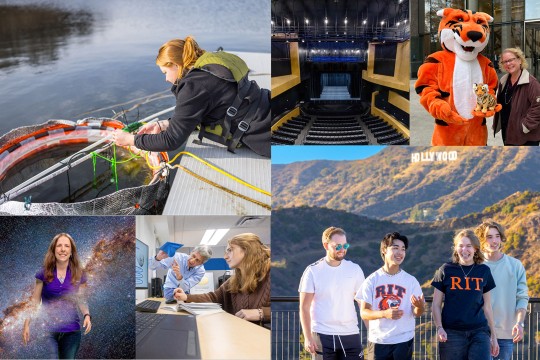

Undergraduate students from packaging science, graphic design and industrial design worked over the semester to improve packaging and branding identity for Milwaukee Tools and its Shockwave power drill bits as part of the Packaging Systems class challenge.

Undergraduate students from packaging science, graphic design and industrial design at Rochester Institute of Technology worked over the semester to improve packaging and branding identity for Milwaukee Tools and its Shockwave power drill bits—equipment used for both commercial and residential construction.

Team Brute Force and Team Imperium were the overall winners of the Packaging Systems class challenge. This is the most recent collaborative project class the three departments have undertaken for students that combines theory with applications, innovation and corporate operations. Companies obtain new ideas from design challenges, and students learn first-hand about product development and packaging— how it can influence consumer purchases, improve users’ experiences and the impact different materials can have on the transportation process and the environment.

Jesse Wolfe

Charlotte Foley, a first-year packaging science student from Raleigh, N.C., checks out the materials supplied by Milwaukee Tool at the beginning of the Packaging Systems class challenge.

Working with the students was Joanne Andrew, a senior packaging engineer with the company. An alumna of RIT’s packaging science program, she came to campus at the outset of the project to talk about the company, its market strategy and to pose the specific challenges the students would have to address for their projects. Andrew participated at design reviews and feedback sessions with each of the teams.

When she returned at the end of the term to judge the six class teams, Andrew found all of them impressive, and making her selection of a top team a difficult one, she said.

“There was something about each of the designs that made them hard to judge,” said Andrew, who has been with the company since 2015, the year she graduated from RIT. “Milwaukee Tool was looking to improve its packaging options, incorporating more sustainable materials and addressing some customer concerns we were hearing, one of which was how users opened the protective packaging.”

That protective packaging was a heavy plastic, clam-shell covering that needed to be cut using scissors. Each team was required to seek alternative materials and styles for both the protective outer packaging and secondary package for the drill bits. During presentations to Andrew, classmates, faculty and guests, the students showed videos of their work and discussed processes undertaken for new designs, market studies, cost estimates and environmental impact information.

Jesse Wolfe

Industrial design students Evan Williams, right, and Laura Woodrow presented design options to Joanne Andrew, left, from Milwaukee Tool during a design challenge to rework the company’s product packaging.

Brute Force’s winning entry was made of lighter paper board that uses two-thirds less PVC and made the outer covering easier to open. The components’ packaging included slide-openers (for better access while on the job site), a ruler on each of the boxes holding the different-sized drill bits, and a bottle opener. Team members are: graphic design students Samantha Abert, Emily Grace Amponin and Anna Schum-Houck; industrial design students Jennifer Schaffer and Brendan Smailer; and packaging science student Bingzhi Zeng.

Imperium 6 designed a package using magnetic bit holders to better secure the different parts. The overall package was 60 percent smaller and would allow for nearly 80 percent more of the packages on pallets, reducing the number of pallets needed for transport and, ultimately, reducing emissions. Team members are: graphic design students Patrick Campbell, Thomas Rothdeutsch and Olivia Sanders; industrial design students Laura Woodrow and Evan Williams; and packaging design student Mary Claire Steinwachs.

When the student videos and prototypes are shown in-house to the company, it can be rejuvenating, said Dan Harel, adjunct professor of industrial design who co-taught the popular course with Lorrie Frear, professor of graphic design, and Karen Proctor, professor of packaging science.

“It can rejuvenate the staff to see the student enthusiasm and hard work,” he said. “The students also recognize that each discipline brings a different skill set to this kind of project. One student commented this was like getting three classes in one. This collaborative style, this experience, this is exactly what industry wants.”

And RIT is preparing them. Over the 10 years the course has been taught, the student teams have worked with major corporations such as Unilever, Mondelez, Kraft Food, Wegmans and Seventh Generation. This was Milwaukee Tool’s first year sponsoring the design challenge. At the start of the fall semester, the company donated tool kits consisting of assorted safety cutters and measuring tools to each of the students.

Several designs have been adapted and used by companies for its current product lines, one previous team received a patent for its design. While some of the designs become property of the sponsoring company, the students are able to discuss the type of work, the challenges and the collaborative solutions as they seek jobs in their respective fields.

Additional teams competing in the design challenge were:

Mallet designed a “luxury product” with less plastic that used a LEGO-style motif to hold the different sized drill bits. “We wanted to focus on sustainability of the product but also make sure that the drill bits didn’t move,” said Laura Olverd, a fourth-year graphic design major.

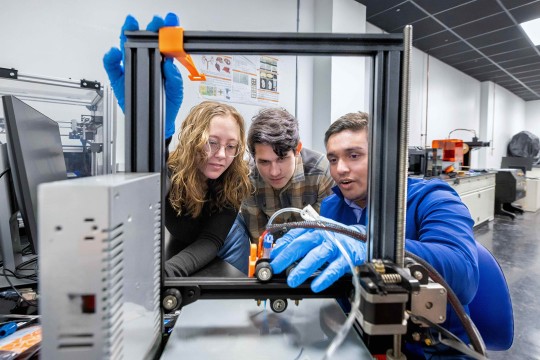

MACK JR designed an easy-access flip case with three panels as compartments for the drill bits. Their “value-add” included a belt clip for holding the different sized bits. Several packaging components were 3D printed.

Out-of-the-Box had the “wow” factor of the zip-open design—a center perforation on their package for easier access to the modular case. It uses 31 percent less materials, and the re-worked, overall packaging would allow for 78 percent more on delivery pallets, decreasing the shipping impact by 44 percent. “We used less plastic but the package remained essentially the same size; it is still protected and a recognized product on the shelf,” said Charles Troncone, a fourth-year student in packaging science.

Maya came up with a new tagline for the drill bits—The starter kit that finishes the job—and re-designed the package with lighter, more sustainable materials as well as used a modular design in compact cases.