Student recognized for research on concrete

Research contributes to findings on using alkali-activated materials increases structural strength

Valeria Gonzalez

Valeria Gonzalez, an undergraduate engineering student, was part of a research team at Rochester institute of Technology that found cement and concrete strength could be improved by more than 50 percent of traditional use by incorporating industrial waste, specifically alkali-activated slag from blast furnaces.

Her project work was recognized at the Society of Hispanic Professional Engineers annual conference this past winter, and her research, “Factors affecting the setting time and compressive strength of alkali-activated ground granulated blast furnace slag reinforced with Wollastonite,” was awarded the best undergraduate research paper.

Gonzalez’s work helped to confirm the durability of high performance concrete. The inclusion of alkali-activated slag, waste by-product, has the potential to improve the materials strength of concrete used for high temperature barriers and aerospace applications. Alkali-activated materials are also considered sustainable because of their limited release of carbon dioxide into the atmosphere.

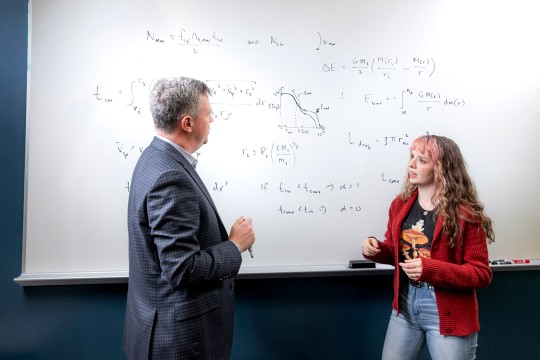

“From the beginning I was very interested in this project. I had the opportunity to use skills I learned in industrial engineering and sustainable engineering. It was a perfect fit,” said Gonzalez, a fifth-year dual degree industrial and systems engineering student in RIT’s Kate Gleason College of Engineering. She worked closely with Benjamin Varela, professor of mechanical engineering, on his research team for the past two years. Varela has been instrumental in the development of alternative materials solutions for high performance concrete and cement.

“We have been trying to create ‘green’ cements and through some of Valeria’s work we have a formula which is three times stronger that normal cement,” Varela said.

Alkali activation, the chemical reaction of two aggregate materials, produces a paste that can be hardened at a lower temperature. This alternative to traditional cement is an emerging technology with the potential to develop high performance, cement-less construction materials, said Gonzalez. The RIT researchers described the use of blast furnace slag, mixed with a potassium-based solution and further, with the mineral Wollastonite, resulted in the strength of the mixture increasing by 53 percent over traditional concrete strength measurements.

The United States uses approximately 260 million cubic yards of ready-mixed concrete each year for structures such as highways, airport facilities and runways, buildings and bridges, according to the Portland Cement Association. The national industry organization supports research for improvements to cement and concrete, particularly in the areas of sustainability and increased durability as well as cost-effectiveness alternatives to asphalt.

The research into further developing this material will continue. Gonzalez had her findings published this past March by the International Journal of Innovative Technology and Exploring Engineering. After graduation in May, she will present findings at its international conference in the Czech Republic later this summer.

“It makes me proud that we are one of the few from the U.S. who had papers accepted for this conference,” said Gonzalez. “It is a great opportunity to get international experience and I enjoy sharing this information about what we have learned so far.”