Mechanical and Mechatronics Engineering Technology Department

- RIT/

- College of Engineering Technology/

- Academics/

- Departments/

- Mechanical and Mechatronics Engineering Technology

Overview

The Department of Mechanical and Mechatronics Engineering Technology (MMET) is comprised of three distinct disciplines that offer intense experiential education in manufacturing, mechanical, or electrical mechanical engineering technology. The students from these disciplines graduate as engineers with the ability to adapt, grow, and succeed in a highly competitive engineering workplace. Full time placements upon graduation have ranged from 95% to 98%.

Accreditation

Visit the college’s accreditation page for information on enrollment and graduation data, program educational objectives, and student outcomes.

2nd

Largest mechanical engineering technology program in the U.S.

700+

students studying in undergraduate and graduate degree programs in the department

6

Robotics, Aerospace, Industrial Automation, Manufacturing, Surface Mount Electronics and Plastics.

Latest News

-

January 14, 2026

RIT engineering technology professor becomes president-elect of ASEE organization

RIT professor Martin Gordon was recently voted president-elect of the American Society for Engineering Education.

-

November 19, 2025

Club sports help students find their fit

Club sports are a big part of student life at the university. Every year, about 2,000 students are involved with the nearly 50 different club sports. For many, it scratches that competitive itch. For others, it’s a chance to try something new, find a community, and stay active.

-

November 10, 2025

NTID alumnus is driven to lead

As a business team leader at the company’s Pennsylvania plant, Trauger oversees operations on the cab-over line, where the refuse collection trucks are assembled, with a focus on safety, quality, and delivery.

Featured Work and Profiles

-

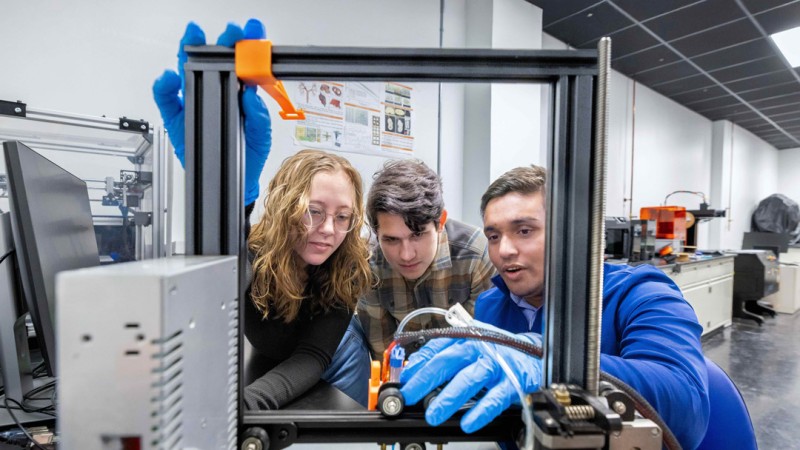

Faculty and undergrads formulate a new “recipe” for stronger bio-printed tissue

MD Ahasan Habib, Christopher Lewis Undergraduate students Riley Rohauer and Perrin Woods work with Assistant Professor Ahasan Habib to develop hybrid hydrogels that can produce bio-scaffolds for tissue engineering using a novel hybrid...

Read More about Faculty and undergrads formulate a new “recipe” for stronger bio-printed tissue -

Faculty-researcher is pioneering self-healing materials for 3D printing

Christopher Lewis Imagine a 3D-printed part that never needs replacement! We're pioneering self-healing materials for 3D printing. This groundbreaking technology, led by CET faculty researcher Dr. Christopher Lewis,...

Read More about Faculty-researcher is pioneering self-healing materials for 3D printing -

The Spark of Success: How Students Forged the First NYS American Welding Society Chapter

It took a spark of an idea from CET students to forge the first American Welding Society student chapter in New York State. The club now unites over 50 members from majors as diverse as engineering...

Read More about The Spark of Success: How Students Forged the First NYS American Welding Society Chapter -

NTID/CET Alumna Launches the Future of Tide and Gain as a P&G Engineer

Kayley Judd ’25 Kayley Judd ’25 landed a career solving the toughest problems that ensure global staples, like Tide and Gain, make it seamlessly from the factory to your laundry room. As a Fabric Care Packaging...

Read More about NTID/CET Alumna Launches the Future of Tide and Gain as a P&G Engineer -

Undecided to Unstoppable: An Alum's Drive to Innovate as a GM Manufacturing Process Engineer

Discover how an undecided RIT student found his calling in Mechanical Engineering Technology, graduated in '24, is now powering iconic vehicles as a Manufacturing Process Engineer at General Motors.

Read More about Undecided to Unstoppable: An Alum's Drive to Innovate as a GM Manufacturing Process Engineer -

Taking Flight on Co-op: Student Discovers her Passion for Production at Honda Aircraft Co.

Allison Fink, a Manufacturing Engineering Technology student, always wondered how machines worked. Her co-op at Honda Aircraft Co. gave her the ultimate real-world experience, taking her from the...

Read More about Taking Flight on Co-op: Student Discovers her Passion for Production at Honda Aircraft Co.

Undergraduate Programs

The department’s unique curriculum supports engineering education to include manufacturing processes, mechanical design, electrical and mechanical systems integration, product life-cycle engineering and management, and conventional and alternative energy systems development. The curriculum also includes cooperative education work experiences. Students are introduced to the excitement of engineering in their very first semester with copious laboratory experiences. The faculty and laboratories that support the three disciplines are under one academic unit and provide interdisciplinary education that enables students to be successful in today’s global engineering and manufacturing environment.

RIT's mechanical engineering technology degree teaches you how products and machinery work through course work and hands-on experiences.

Learn more about the Mechanical Engineering Technology BS programRIT's BS in Mechatronics Engineering Technology prepares students to drive the design and development of smart products by integrating electrical and mechanical systems.

Learn more about the Mechatronics Engineering Technology BS programRIT's Product Design option of the Mechanical Engineering Technology BS specializes in the study of all engineering aspects of product ideation, innovation, design, and validation.

Learn more about the Product Design Option - Mechanical Engineering Technology BS programSpecialize in robotics, automation, and controls with a focus on industrial and cobot systems.

Learn more about the Robotics and Automation Option - Mechanical Engineering Technology BS programRIT’s robotics and manufacturing engineering technology major prepares you to become an engineer well-versed in advanced manufacturing technologies and automation.

Learn more about the Robotics and Manufacturing Engineering Technology BS programThe manufacturing systems minor provides students with a foundation in the professional study and practice of manufacturing operations. Students develop a required foundation of manufacturing processes and statistics, then they select three advanced manufacturing courses to fulfill the following requirements: quality engineering principles, engineering economics, lean production and supply systems, integrated design for manufacturing and assembly, or electronics manufacturing.

Learn more about the Manufacturing Systems Minor programThe plastics engineering and technology minor provides students with a foundation in the professional study of plastic materials and their applications. This minor provides a broad perspective in plastics and polymer engineering/technology including the preparation of polymeric materials and polymer composites, their characterization, and the design and processing of these materials into useful products. The minor also includes a plastics characterization laboratory experience.

Learn more about the Plastics Engineering and Technology Minor programThe robotics and automation minor provides students with a foundation in the professional study and practice of programming, using, and working with industrial robots and the industrial automation systems used in the manufacturing environment. It provides a broad perspective that includes automation components, automation systems (hardware and software), industrial robots (hardware and software), and specific issues to implementing industrial robotic systems in the electronics manufacturing environment. It also includes learning and practice in developing automation/robotic code to accomplish specific functions across the major industrial automation software tools.

Learn more about the Robotics and Automation Minor programThe surface mount electronics manufacturing minor provides students with a foundation in the professional study and practice of the manufacturing of electronic circuits with components placed directly on printed circuit boards (surface mount technology). This minor provides a broad perspective that includes surface mount devices, assembly, lean production, and quality topics. It also includes learning and practice in electronic component layout, placement, high volume production, materials, circuit board design for manufacturability (design for manufacturability - DFM) and process controls.

Learn more about the Surface Mount Electronics Manufacturing Minor programGraduate Programs

Through the master of science program in manufacturing and mechanical systems integration, the department is able to provide opportunities for continuing education to many of our students interested in pursuing their graduate education and also support our industry partners with their need for enhancing their workforce. This program is designed for individuals who wish to achieve competency in the effective integration of the computing, manufacturing, design, quality, and management functions in any manufacturing or engineering enterprise.

The mechatronics and mechanical systems MS combines engineering, robotics, automation, and computing to create smart products and manufacturing systems.

Learn more about the Mechatronics and Mechanical Systems MS programIndustrial Advisory Board

The Department of Mechanical and Mechatronics Engineering Technology Industrial Advisory Board is comprised of successful engineers, managers, and leaders who work at various businesses throughout the world. Together they review the MMET department curriculum to ensure that our programs remain up-to-date and respond to industry changes. The committee has annual meetings at the end of the academic year. Learn more about the professionals that comprise our advisory committee.

Student Resources

The MMET Department offers a variety of resources for our students such as:

- Academic Advisors

- Student Clubs and Organizations

- Change of Program Information

- Technical Information and Support

- Software Help

- CET Student Scholarships and Awards

Visit our Student Resources page for more information.