Materials Science Laboratory

Materials Science Laboratory

We apply materials science to develop sustainable solutions that address critical industry needs for energy efficiency, resource conservation, and material performance.

The Materials Science Laboratory at RIT’s Golisano Institute for Sustainability (GIS) provides manufacturers small and large, government agencies, and academic research partners with state-of-the-art technologies and leading expertise in material science and engineering. The lab is used to design, develop, and characterize materials for a wide range of industrial applications.

Research

Our research advances the processing-structure-property relationships in materials through modeling and experimentation. We are currently conducting research in the following key areas:

Sustainable Materials Design

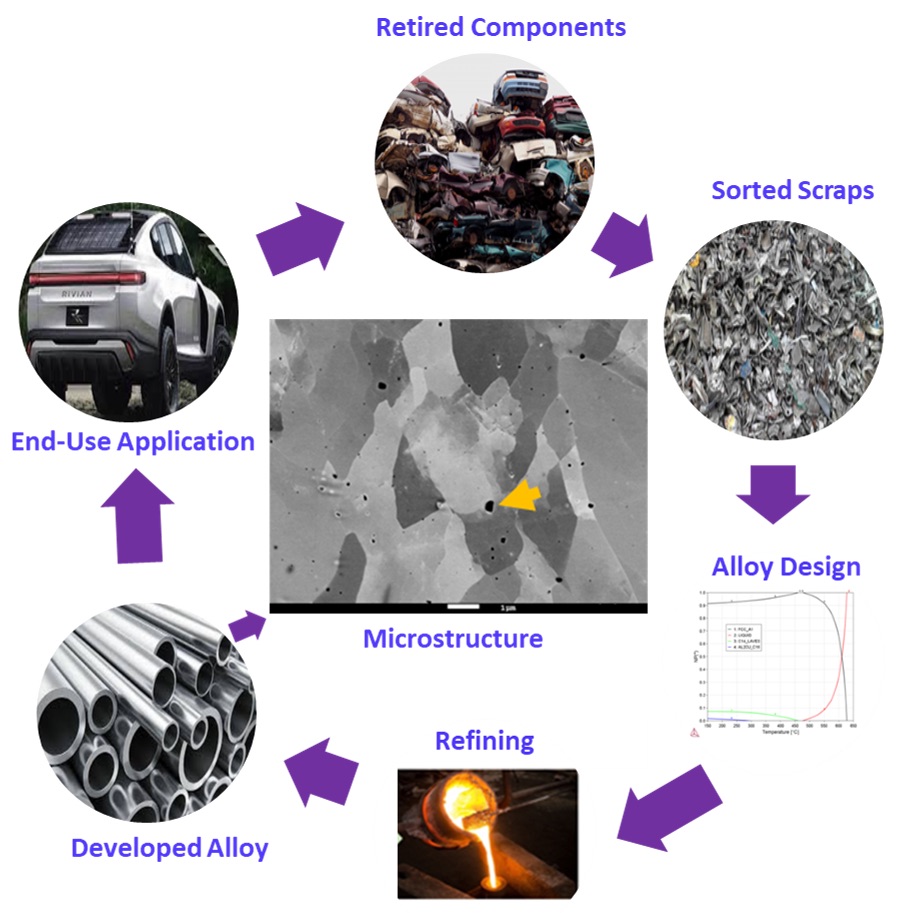

Materials—how they are made and how they perform—are critical to a sustainable future. Our research focuses on developing high-performance materials that can endure extreme environments through computationally aided, high-throughput experimentation, such as is needed in certain clean-energy applications. We also design alloys that reduce reliance on critical elements like rare earths, cobalt, and nickel, while also exploring high-performance alloys with increased recycled content.

Featured work:

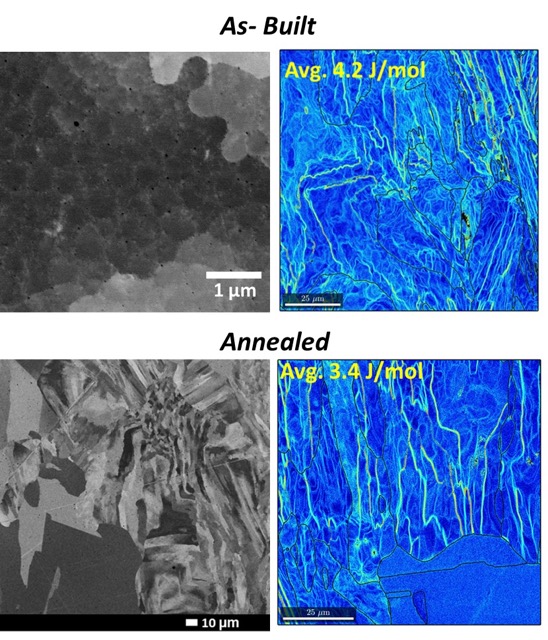

Due to their exceptional thermal stability, additively manufactured (AM) materials show great potential for high-temperature applications in industries such as aerospace, energy, and defense. Using advanced characterization techniques, this project aims to shed light on the fundamental mechanisms responsible for the higher thermal stability of AM-built materials. This knowledge is key to controlling AM microstructures to enhance thermal stability, paving the way for their application in next-generation high-performance systems.

Due to their exceptional thermal stability, additively manufactured (AM) materials show great potential for high-temperature applications in industries such as aerospace, energy, and defense. Using advanced characterization techniques, this project aims to shed light on the fundamental mechanisms responsible for the higher thermal stability of AM-built materials. This knowledge is key to controlling AM microstructures to enhance thermal stability, paving the way for their application in next-generation high-performance systems.

Better understanding of how impurities—like sulfur, phosphorus, and other non-metallic inclusions —affect the microstructure evolution and mechanical properties of high-strength steel is critical for designing scrap-tolerant alloys, especially as the steel industry seeks to use more recycled scrap. This research will analyze how these impurities influence solidification, grain structure, and overall material performance. The study aims to provide a foundation for developing high-strength steels that can tolerate a greater proportion of recycled content while maintaining desirable mechanical properties to support more sustainable metal production.

Better understanding of how impurities—like sulfur, phosphorus, and other non-metallic inclusions —affect the microstructure evolution and mechanical properties of high-strength steel is critical for designing scrap-tolerant alloys, especially as the steel industry seeks to use more recycled scrap. This research will analyze how these impurities influence solidification, grain structure, and overall material performance. The study aims to provide a foundation for developing high-strength steels that can tolerate a greater proportion of recycled content while maintaining desirable mechanical properties to support more sustainable metal production.

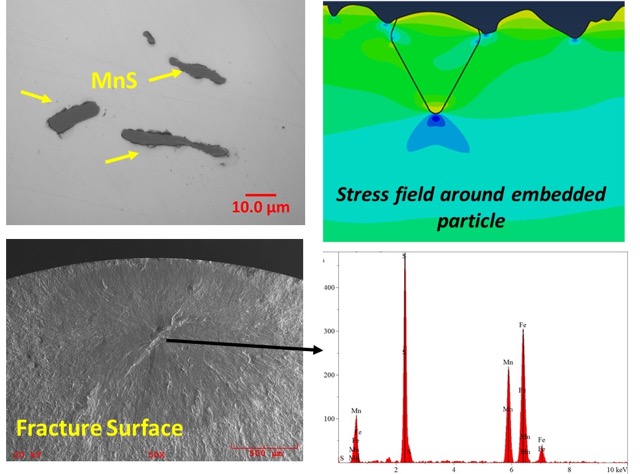

Manganese sulfide (MnS) inclusions are commonly found in advanced high-strength steels and have a significant impact on mechanical performance. Factors such as their size, shape, distribution, and orientation relative to the loading direction, as well as local strain caused by manufacturing or post-processing treatments (like induction-hardening), can influence fatigue behavior. This project aims to analyze the strain field surrounding MnS inclusions using a combination of high-resolution electron backscatter diffraction and finite element modeling. By studying the strain fields around various types of inclusions, this project seeks to enhance the understanding of how inclusions affect the fatigue of high-strength steel.

Manganese sulfide (MnS) inclusions are commonly found in advanced high-strength steels and have a significant impact on mechanical performance. Factors such as their size, shape, distribution, and orientation relative to the loading direction, as well as local strain caused by manufacturing or post-processing treatments (like induction-hardening), can influence fatigue behavior. This project aims to analyze the strain field surrounding MnS inclusions using a combination of high-resolution electron backscatter diffraction and finite element modeling. By studying the strain fields around various types of inclusions, this project seeks to enhance the understanding of how inclusions affect the fatigue of high-strength steel.

Advanced Manufacturing and Materials Processing

Our research investigates novel manufacturing techniques to produce high-performance materials in a cost-effective, energy-efficient, and scalable way. We optimize processing parameters using in-situ monitoring and post-process characterization to synthesize high-quality materials with enhanced properties, both as base materials and as coatings. We also explore post-processing treatments to improve material performance for demanding applications, such as those involving extreme temperatures.

Featured work:

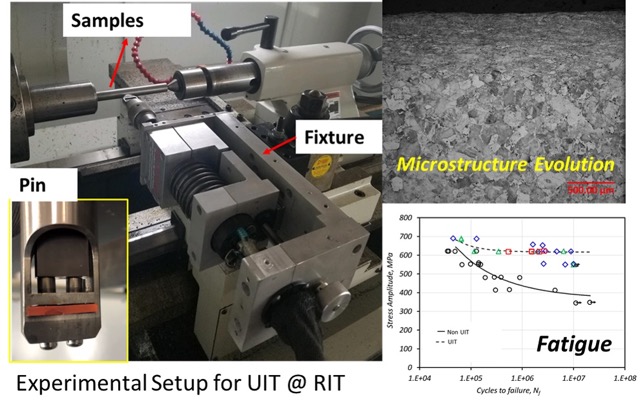

UIT is a needle-peening process that enhances fatigue life. However, UIT can negatively affect component integrity by increasing surface roughness and introducing stress concentrations because of high-energy impacts. UIT’s overall impact on fatigue life depends on the balance between beneficial effects, such as strain-hardening and grain-refinement, and detrimental effects, such as stress risers. Uncertainties about the correlation between UIT-induced microstructural changes and fatigue performance have hindered the method’s widespread application. This study aims to establish a quantitative link between UIT parameters, microstructural evolution, and fatigue performance in steels with varying microstructures (e.g., ferrite-pearlite or tempered martensite).

UIT is a needle-peening process that enhances fatigue life. However, UIT can negatively affect component integrity by increasing surface roughness and introducing stress concentrations because of high-energy impacts. UIT’s overall impact on fatigue life depends on the balance between beneficial effects, such as strain-hardening and grain-refinement, and detrimental effects, such as stress risers. Uncertainties about the correlation between UIT-induced microstructural changes and fatigue performance have hindered the method’s widespread application. This study aims to establish a quantitative link between UIT parameters, microstructural evolution, and fatigue performance in steels with varying microstructures (e.g., ferrite-pearlite or tempered martensite).

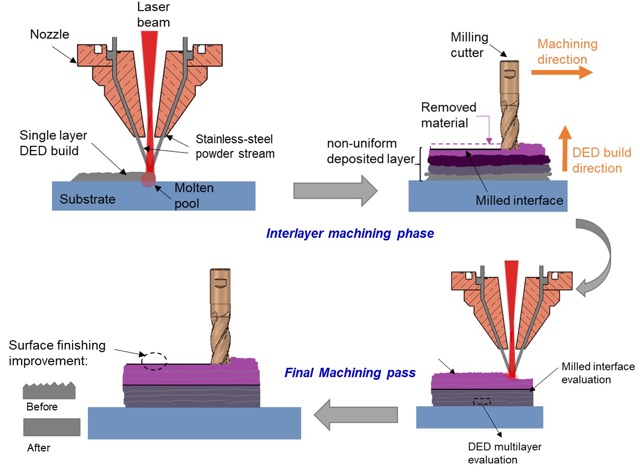

Post-build machining of stainless-steel components is typically used to improve surface finish and dimensional accuracy. However, applying interlayer machining during DED may provide better control, especially in complex geometries and high-curvature areas. By examining how interlayer machining influences microstructural features and mechanical performance, this research seeks to optimize DED processes to improve component quality and reliability in high-performance applications.

Post-build machining of stainless-steel components is typically used to improve surface finish and dimensional accuracy. However, applying interlayer machining during DED may provide better control, especially in complex geometries and high-curvature areas. By examining how interlayer machining influences microstructural features and mechanical performance, this research seeks to optimize DED processes to improve component quality and reliability in high-performance applications.

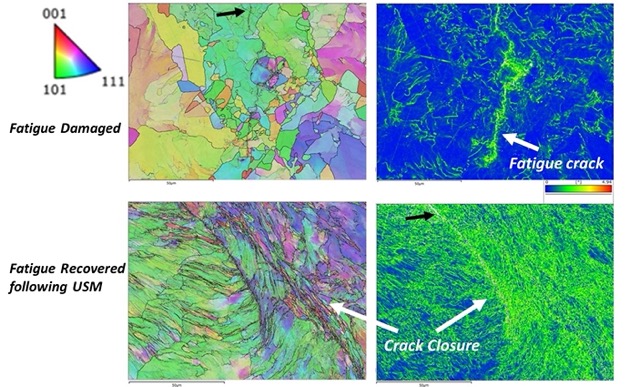

Fatigue-induced damage often shortens the life of high-strength steels in critical applications. USM offers a promising solution by introducing compressive residual stresses and refining surface microstructures in the vicinity of the crack, potentially reversing the detrimental effects of fatigue damage. In this study, steel samples are pre-fatigued to various levels of damage and then treated with USM. Fatigue testing, microstructural analysis, and finite element simulations are conducted to assess the effects of USM on fatigue life, crack closure, and stress distribution.

Fatigue-induced damage often shortens the life of high-strength steels in critical applications. USM offers a promising solution by introducing compressive residual stresses and refining surface microstructures in the vicinity of the crack, potentially reversing the detrimental effects of fatigue damage. In this study, steel samples are pre-fatigued to various levels of damage and then treated with USM. Fatigue testing, microstructural analysis, and finite element simulations are conducted to assess the effects of USM on fatigue life, crack closure, and stress distribution.

Remanufacturing and Recycling

Our research in remanufacturing and recycling focuses on extending the life of critical components to promote resource efficiency. We develop advanced repair technologies to restore high-value parts to near-original performance, addressing the causes of mechanical degradation and defects. We also investigate green hydrometallurgical methods for recycling, using eco-friendly reagents to recover valuable materials from spent products.

Featured work:

HSLC is a promising technology for repairing thin-walled and high-strength components, overcoming challenges posed by traditional methods. By accelerating the cladding process, HSLC reduces the melt-pool size, lowering heat input and minimizing the risk of part distortion or damage. However, nozzle overheating has been a persistent issue, causing powder to stick and distribute unevenly. Current research is focused on developing a new nozzle design with enhanced cooling and improved powder focus to optimize HSLC for broader remanufacturing applications.

Ductile and grey iron are often used in large castings because they cast easily and achieve high compressive strength. However, the high level of carbon-silicon in these types of iron makes it hard to repair through welding. Existing welding methods are either too quick and prone to cracking or too slow and prone to distortion. This project explores using cold metal transfer (CMT) to create a reliable, low-temperature repair process that avoids excessive heat and long cooling times. CMT's precise control maximizes wire-melting over substrate-heating. By alloying magnesium (Mg) into the weld, the process aims to promote nodular graphite growth, reducing brittle phases at the weld interface.

Conventional fusion-based techniques for repairing aluminum and stainless steel result in cracking, voids, and a weakened heat-affected zone. In this study, FSD was investigated as an alternative, solid-state repair method for avoiding these effects by depositing materials below melting point. FSD’s effectiveness was successfully demonstrated as a means for repairing both aluminum and stainless steel, with a focus on maintaining mechanical integrity, achieving strong metallurgical bonding, and understanding the microstructural evolution in the repaired areas. This solid-state approach shows great potential for use in high-performance applications in the automotive, aerospace, marine, and defense industries.

Read more:

- “Repair of aluminum 6061 plate by additive friction stir deposition” (research article)

- “Evaluation of additive friction stir deposition of AISI 316L for repairing surface material loss in AISI 4340” (research article)

Non-destructive evaluation (NDE) can be used to detect porosity and disbonds in thermal spray coatings. Four NDE methods—acousto-ultrasonics, vibrothermography, thermal wave infrared (IR) imaging, and flash IR thermography—were evaluated in this study to identify a real-time, in-process inspection method to improve remanufacturing efficiency. Testing on stainless-steel coatings revealed that thermal wave IR imaging and flash IR thermography offered the best accuracy and reproducibility. Acousto-ultrasonics and vibrothermography were deemed unsuitable due to limitations in accuracy and integration. These findings mark an important step toward improving quality control, reducing rework, and enhancing energy efficiency in thermal spray repairs.

More efficient methods for removing epoxy and silicone potting materials could enhance testing, repair, and remanufacturing of a wider range of printed circuit boards (PCBs). This project evaluated micro-abrasion and laser-ablation techniques for their effectiveness in removing potting materials from PCBs. While laser ablation proved particularly promising for epoxy-based potting, challenges persisted in achieving precise control near sensitive PCB components. Material-removal rates aligned with project goals, but ongoing research is needed to refine the process for more delicate areas of the board.

Development of Fire Protection Materials

Our aim is to develop and optimize fire-resistant materials to enhance safety across various environments. By integrating expertise in chemistry, materials science, engineering, and physics, we focus on improving heat resistance, flame retardance, and smoke suppression. The Bal Dixit High Temperature Materials Lab provides extensive resources to conduct advanced experimental and computational methods in this area.

Technical Assistance

We partner with companies as an extended workbench to support a variety of process-, product-, or application-specific initiatives related to materials. We can provide support at the product-design phase through to final testing and validation. We also offer expertise in techniques for sustaining and recovering value from end-of-life materials, equipment, and products.

Services

Materials characterization

- Microstructural analysis

- Chemical Composition analysis

- Mechanical properties evaluation

- Non-destructive testing

Corrosion and wear studies

- Corrosion resistance testing

- Wear resistance evaluation

- Coating adhesion testing

Failure analysis

- Root-cause analysis of material failures

- Fractography and failure mode identification

Materials selection

- Materials selection guidelines for specific application

- Process improvement and troubleshooting

- Custom material solution for extreme environments

Case Studies

Objective:

- Investigate whether surface contamination from the assembly process is a cause of increased friction in ceramic bearings.

Application:

- High-temperature manufacturing process

Approach:

- Compare a control ceramic bearing to a contaminated one to identify variations in defects, surface chemistry, and contamination.

Methodology:

- Inspect both component samples using electron microscope (SEM) scanning and energy dispersive spectroscopy (EDS).

- Clean both samples in separate ultrasonic baths and examine any contaminants extracted from the bath liquid after cleaning.

- Re-inspect both samples to analyze any remaining contamination after cleaning using SEM-EDS.

- Bake the control sample overnight in accordance with application.

- Verify the component’s function and perform final SEM-EDS inspection.

Results:

The observations from the test results provided valuable information about the source of the contamination causing the bearings to fail. The client was able to use these insights to improve the relevant system.

Objective:

- Evaluate the material strength of a geotextile bag for filtering drinking water and assess how implementing heat-sealed lap joints affect its performance.

Application:

- water-filtration systems

Approach:

- Conduct tensile and lap-shear tests on the geotextile material to measure strength and joint integrity relative to loading calculated for the application.

Methodology:

- Fabricate custom sample-holder fixtures for testing.

- Perform tensile tests using an Instron® machine to evaluate the material's strength.

- Conduct lap-shear tests to assess the strength of heat-sealed lap joints.

Results:

Testing was able to quantify the performance of the customer’s proposed material after undergoing the manufacturing process steps and compare those against system requirements

Objective:

- Investigate failed condenser tubes to uncover the root cause of how they cracked and why.

Application:

- water-based cooling systems

Approach:

- Use optical and scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS) to analyze the tubes.

Methodology:

- Optically examine the tubes using light-microscopes to analyze the crack patterns.

- Dissect the cooling tubes to access crack surfaces.

- Use SEM-EDS to evaluate surface deposits on the cracked tubes and the base material composition.

Results:

- The optical examination revealed cracks on the tensile side with triangular branching patterns, typical of fatigue cracking.

- EDS analysis of a deposit layer on the inner diameter of the tube cracks detected calcium, phosphorus, and magnesium, along with sodium and chlorine.

- The analysis revealed the presence of agents corrosive to the base material as well as tensile loading caused by the condenser tubes supports, suggesting that the failure was the result of stress corrosion cracking (SCC).

Objective:

- Determine the effects on the performance of a high-speed induction tempering process after quenching of a type of high-hard steel.

Application:

- development of high wear- and penetration-resistant materials

Approach:

- Compare and analyze the mechanical properties and microstructure of quenched steel plates before and after induction tempering.

Methodology:

- Adjust the high-speed manufacturing process to treat the steel plates at different temperatures and document changes in ductility, hardness, tensile-strength, and elongation performance.

- Calculate the percent area reduction to measure ductility as a more accurate method for evaluating process changes than tracking percent elongation through tensile testing.

Results:

Optimized the annealing process of the steel plates to achieve specification requirements by reducing tensile properties but improving ductility.

Objective:

- Evaluate multiple cleaning processes for remanufacturing to determine their effects on masking cracks prior to non-destructive evaluation (NDE) and their ability to remove paint.

Application:

- aircraft-engine remanufacturing

Approach:

- Design an experiment to document any distortion on an aluminum substrate caused by alternative cleaning processes compared to conventional cleaning.

Methodology:

- Conduct dedicated studies for each cleaning technique on dirty components and parts fabricated with seeded defects that simulated cracks.

Results:

Testing identified the preferred methods to clean the sensitive components without masking underlying cracks and the optimal parameters at which to run the cleaning equipment.

Get in touch to learn more about our technical assistance services.

Technical Capabilities

Our lab includes state-of-the-art equipment for processing, characterizing, and analyzing the properties of a wide range of materials, including metals, polymers, and ceramics.

Processing

Equipped with a high-power 3 kW fiber laser, the LENS 860 reduces manufacturing time for building, repairing, or coating parts. It features a rugged CNC platform with a 16-tool automatic tool changer (ATC) and an 8,000 RPM spindle for machining operations. This versatile system is well-suited for direct energy deposition of metallic materials, multi-material joining/fabrication, and the production of graded materials.

Equipped with a high-power 3 kW fiber laser, the LENS 860 reduces manufacturing time for building, repairing, or coating parts. It features a rugged CNC platform with a 16-tool automatic tool changer (ATC) and an 8,000 RPM spindle for machining operations. This versatile system is well-suited for direct energy deposition of metallic materials, multi-material joining/fabrication, and the production of graded materials.

With a spacious build area measuring 250 x 250 x 330 mm, the ProX 300 is capable of printing large metal pieces. It offers exceptional accuracy down to 20 μm, making it an ideal choice for high-quality, industrial-grade 3D printing. It supports a wide range of materials including stainless steel, tool steel, precious metals, alumina, super alloys, and nonferrous alloys.

With a spacious build area measuring 250 x 250 x 330 mm, the ProX 300 is capable of printing large metal pieces. It offers exceptional accuracy down to 20 μm, making it an ideal choice for high-quality, industrial-grade 3D printing. It supports a wide range of materials including stainless steel, tool steel, precious metals, alumina, super alloys, and nonferrous alloys.

This low-pressure (58 to 158 psi) cold spray deposition system is capable of depositing metals, metallic alloys, metal blends, ceramics, and polymers. It is designed for applications such as geometric restoration, corrosion resistance, and wear resistance.

This low-pressure (58 to 158 psi) cold spray deposition system is capable of depositing metals, metallic alloys, metal blends, ceramics, and polymers. It is designed for applications such as geometric restoration, corrosion resistance, and wear resistance.

The CMT welder is capable of providing low heat input and highly stable welding, cladding, and brazing of metallic materials. It is particularly suitable for welding on light-gauge sheets with minimal distortion and for creating special connections using materials such as copper, zinc, and steel/aluminum.

The CMT welder is capable of providing low heat input and highly stable welding, cladding, and brazing of metallic materials. It is particularly suitable for welding on light-gauge sheets with minimal distortion and for creating special connections using materials such as copper, zinc, and steel/aluminum.

The AT-400 high performance thermal spray system combines the benefits of a “push” method wire feeder with the power of a 400-amp arc spray system. It is capable of depositing multiple materials simultaneously, allowing for the production of graded thermal sprayed coatings.

The AT-400 high performance thermal spray system combines the benefits of a “push” method wire feeder with the power of a 400-amp arc spray system. It is capable of depositing multiple materials simultaneously, allowing for the production of graded thermal sprayed coatings.

This 3D Printer is capable of printing polymer parts with complex geometries suitable for functional use. The Selective Laser Sintering technique employed produces parts with good surface finish and accuracy at a rate of 0.79 inches per hour with a build chamber volume of 7.9 x 9.8 x 13 inches.

This 3D Printer is capable of printing polymer parts with complex geometries suitable for functional use. The Selective Laser Sintering technique employed produces parts with good surface finish and accuracy at a rate of 0.79 inches per hour with a build chamber volume of 7.9 x 9.8 x 13 inches.

The system enables the quick construction of parts within a build envelope measuring 254 x 254 x 305 mm. Each material cartridge contains 922 cc of usable material. The Fortus 250mc offers three layer thickness options: .178 mm, .254 mm, and .330 mm.

The system enables the quick construction of parts within a build envelope measuring 254 x 254 x 305 mm. Each material cartridge contains 922 cc of usable material. The Fortus 250mc offers three layer thickness options: .178 mm, .254 mm, and .330 mm.

The equipment consists of a 27 kHz ultrasonic generator with an output voltage of up to 80.6 V, combined with Progress Rail's magnetostrictive transducer. The UIT equipment supports both single and multiple pin configurations, allowing for up to four pins arranged side by side. It has the capability to process a wide range of materials, spanning from soft to hard.

The furnace is capable of heat treating materials up to 1700°C, accommodating a wide range of materials for various types of heat treatment. The large chamber size allows for the heat treatment of samples with different sizes. The use of long-life type "B" thermocouples enables accurate temperature measurement.

The furnace is capable of heat treating materials up to 1700°C, accommodating a wide range of materials for various types of heat treatment. The large chamber size allows for the heat treatment of samples with different sizes. The use of long-life type "B" thermocouples enables accurate temperature measurement.

Characterization

This Field Emission Electron gun SEM system has a variable pressure (VP) mode, which is useful for imaging non-conductive samples. It has secondary, backscattered, and scanning transmission electron microscopy (STEM) detectors. Attached to the microscope are Oxford's Ultim Max 65 energy dispersive spectrometer (EDS) and HKL auto Symmetry Electron Backscatter Diffraction (EBSD) detector.

This Field Emission Electron gun SEM system has a variable pressure (VP) mode, which is useful for imaging non-conductive samples. It has secondary, backscattered, and scanning transmission electron microscopy (STEM) detectors. Attached to the microscope are Oxford's Ultim Max 65 energy dispersive spectrometer (EDS) and HKL auto Symmetry Electron Backscatter Diffraction (EBSD) detector.

The Keyence VHX-700 Digital Microscope is capable of ultra-high resolution imaging, in-depth 3D analysis, and precise measurements for a vast array of materials and components.

This stereo microscope is used for root cause failure analysis, wear rate determinations and surface roughness determinations.

This stereo microscope is used for root cause failure analysis, wear rate determinations and surface roughness determinations.

The Inverted Metallurgical Microscope is used to examine the microscopic mechanisms that affect the behavior of metals, their composites, and alloys.

The Inverted Metallurgical Microscope is used to examine the microscopic mechanisms that affect the behavior of metals, their composites, and alloys.

The Agilent FTIR-4300 Handheld Spectroscopy device is a portable analytical tool, known for its ability to provide rapid, on-site identification and quantification of a diverse range of chemical compounds and materials.

The Agilent FTIR-4300 Handheld Spectroscopy device is a portable analytical tool, known for its ability to provide rapid, on-site identification and quantification of a diverse range of chemical compounds and materials.

The SciAps Z-200 is a portable, cutting-edge handheld Laser Induced Breakdown Spectroscopy (LIBS) analyzer. It enables fast, on-site elemental analysis of various materials without the need for sample preparation, making it suitable for applications such as alloy identification, mining exploration, environmental monitoring, and quality control in manufacturing processes.

The SciAps Z-200 is a portable, cutting-edge handheld Laser Induced Breakdown Spectroscopy (LIBS) analyzer. It enables fast, on-site elemental analysis of various materials without the need for sample preparation, making it suitable for applications such as alloy identification, mining exploration, environmental monitoring, and quality control in manufacturing processes.

The Surface Profolometer is used to determine the roughness of a component's surface.

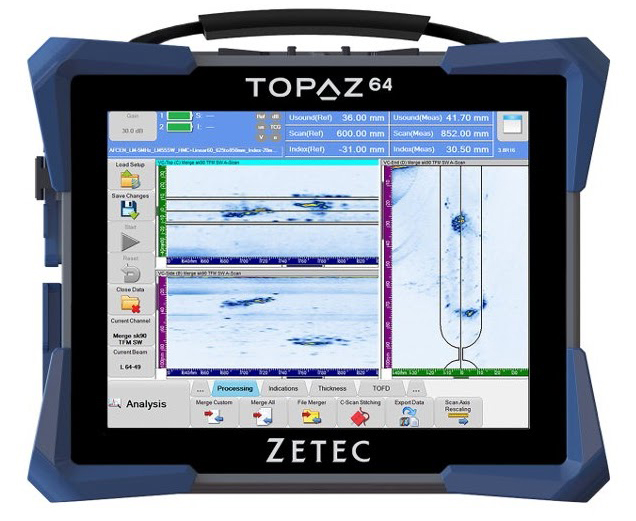

The Zetec TOPAZ 64 is an advanced ultrasonic inspection tool used for non-destructive testing, including code-compliant inspections on thick welds, analysis of composite materials, and examination of complex components across various industries.

The Zetec TOPAZ 64 is an advanced ultrasonic inspection tool used for non-destructive testing, including code-compliant inspections on thick welds, analysis of composite materials, and examination of complex components across various industries.

The Magnaflux ZA-1227 system, as a compact fluorescent penetrant inspection tool, can effectively identify surface-breaking defects, ensure the structural integrity of aerospace fasteners, evaluate the reliability of automotive parts, and validate the quality of surgical implants.

The Magnaflux ZA-1227 system, as a compact fluorescent penetrant inspection tool, can effectively identify surface-breaking defects, ensure the structural integrity of aerospace fasteners, evaluate the reliability of automotive parts, and validate the quality of surgical implants.

Properties

This Servohydraulic Test Frame is used for the quasi-static, three/four-point bending, axial, and bend fatigue testing of materials.

This Servohydraulic Test Frame is used for the quasi-static, three/four-point bending, axial, and bend fatigue testing of materials.

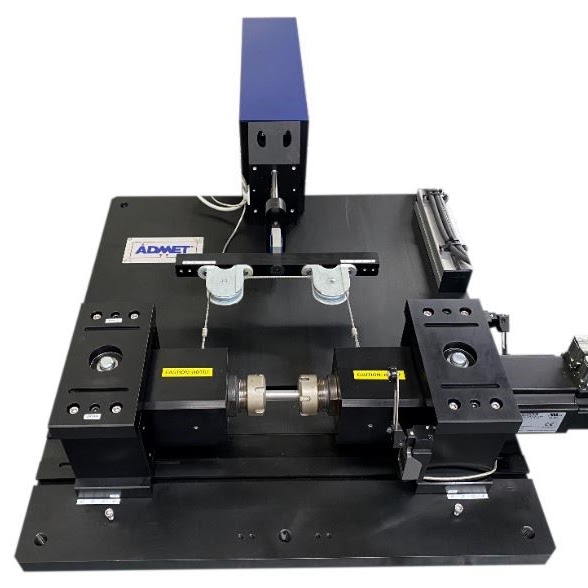

The eXpert 9300 series Rotating Beam Fatigue Test Systems feature a dual spindle system design, exerting uniform bending stress across the entire test specimen. They are capable of performing rotating beam fatigue tests at speeds up to 6,000 rpm (100Hz) and can handle bending moments of up to 100Nm.

The eXpert 9300 series Rotating Beam Fatigue Test Systems feature a dual spindle system design, exerting uniform bending stress across the entire test specimen. They are capable of performing rotating beam fatigue tests at speeds up to 6,000 rpm (100Hz) and can handle bending moments of up to 100Nm.

The LM248 AT is a versatile testing instrument with high-intensity LED illumination, a wide load range (1gf to 2000gf), automatic hardness calculation, dual indenters (Knoop and Vickers), and a color touch-panel display. It offers automatic hardness conversion and the ability to evaluate Fracture Toughness Value (Kc) for fine ceramics and hard-faced materials

The Starrett 3815 Rockwell Hardness Tester is a versatile bench-top unit offering precise Rockwell and Superficial Rockwell tests, enabling applications in testing the macro-hardness of metal alloys, ceramics, and plastics, as well as evaluating heat treatments and coating hardness.

The Starrett 3815 Rockwell Hardness Tester is a versatile bench-top unit offering precise Rockwell and Superficial Rockwell tests, enabling applications in testing the macro-hardness of metal alloys, ceramics, and plastics, as well as evaluating heat treatments and coating hardness.

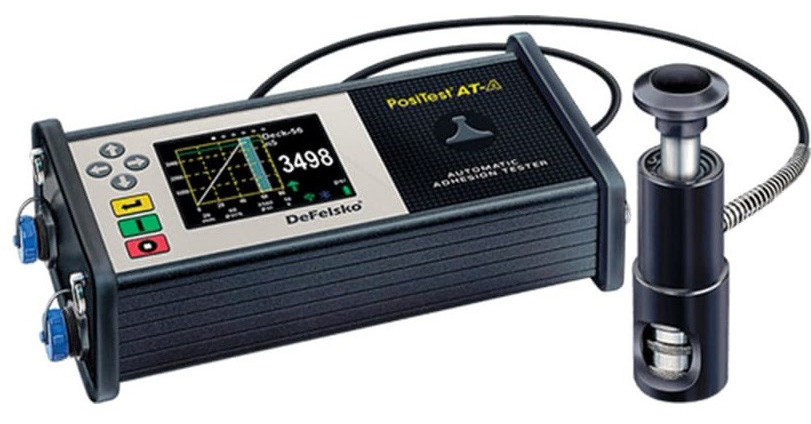

DeFelsko Adhesion Pull Testing accurately measures coating adhesion on various substrates like metal, wood, and concrete, using different stand-offs and single-use dollies, in a robust, environmentally sealed enclosure for reliable results across a range of bond strengths.

DeFelsko Adhesion Pull Testing accurately measures coating adhesion on various substrates like metal, wood, and concrete, using different stand-offs and single-use dollies, in a robust, environmentally sealed enclosure for reliable results across a range of bond strengths.

The Reciprocating Wear Test measures the wear resistance and frictional properties of materials by repetitively sliding a test piece against a counter-surface under controlled conditions.

The Reciprocating Wear Test measures the wear resistance and frictional properties of materials by repetitively sliding a test piece against a counter-surface under controlled conditions.

Our Team

Our team of dedicated faculty, engineers, and researchers brings deep expertise in advanced materials characterization to better understand material behavior within industrial applications. As part of a world-class research university, we have access to cutting-edge technologies, laboratory facilities, and testbeds.