Businesses, consumers save with ‘smart connector’

RIT and PPC Corp. to produce sensor that detects telecommunications equipment failures

Provided by Robert Bowman

The Smart Connector, a new sensor device, is installed in the connecting units of coaxial cables to provide real-time information about primary failure modes in radio-frequency cables. Researchers in RIT’s Kate Gleason College of Engineering and PPC, a Syracuse-based telecommunications connector equipment company, developed the device.

Deterioration and damage to cellular telecommunications cables cost organizations and customers millions in lost revenue and services in the always-on digital economy. A new “smart sensor” device, smaller than a quarter, might alleviate some of the impact.

Researchers at Rochester Institute of Technology and PPC Corp. have developed the Smart Connector, a sensor that once installed in the connecting units of coaxial cables can provide information about equipment damage and pinpoint the exact location through self-diagnosing technologies—some of the most advanced in the field today.

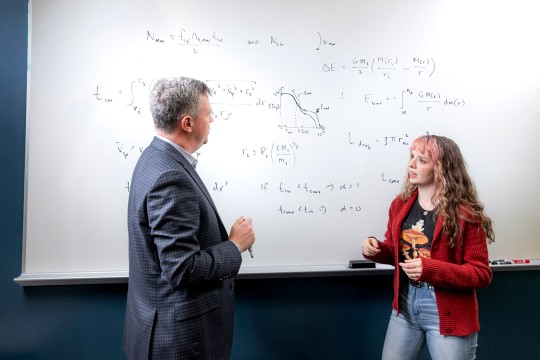

The smart sensor is one outcome of corporate-research-and-development initiatives established at RIT that have grown over the past few years. The university and PPC Corp. signed a licensing agreement in June. Both parties are in the process of final testing and technology transfer, says Robert Bowman, professor of electrical and microelectronic engineering in RIT’s Kate Gleason College of Engineering.

The university demonstrated the feasibility of the technology and is working with PPC to further test the manufactured product, Bowman explains.

“It’s one thing to conduct laboratory testing and demonstrate viability, it’s another thing to get it into a product. PPC worked very closely with us during this research effort, and we’ll work with them as they try to integrate this technology into their product line.”

Bowman and his research group worked with Noah Montena, principal engineer at PPC, a Syracuse-based telecommunications radio-frequency, or RF, connector equipment company, to design the sensor-disc system. The system monitors the primary failure modes in RF cables. Each sensor-disc contains a unique site identifier, monitors critical conditions and reports the sensor status using a technique called back scatter telemetry. Each smart connector is capable of activating or powering-down its energy capacity by extracting miniscule amounts of radio frequency energy from the coaxial cables.

“This technology is really exciting, and the impact it could have on the industry is only just becoming apparent,” says Montena. “Up until now, connector and equipment failures could be detected only after tower capacity had been diminished, and only pinpointed on-site with the system shut down.”

The smart sensors have been designed from the beginning with simplicity, robustness and cost-effectiveness in mind, and one of the advantages of collaborating on the research has been the communication of manufacturing considerations as design decisions get made, Montena adds.

“Beyond cellular connectors, it is easy to imagine this technology finding a place in other high value, or ‘can’t fail’ applications such as communications or internal networks in spacecraft or aircraft. I look forward to uncovering all the possibilities.”