What's being made in the SHED

Making at RIT has hit a new level now that several makerspaces in the Student Hall for Exploration and Development (SHED) have opened to provide students access to equipment and support for classwork, club advancement, and personal projects.

“It’s inspiring to witness a dynamic environment where students freely express their creativity and foster innovation,” said Tiffany Brodner, the SHED’s executive director.

The $120 million SHED, which opened last fall, is RIT’s biggest capital project since the campus moved to Henrietta, N.Y., in 1968. With its five extra-large classrooms, seven makerspaces, performing arts studios, and glass box theater, the SHED complex is made for a new generation of RIT students.

The makerspaces are spread across three floors. The first floor includes machines that can cut wood and plastic precisely with lasers, as well as a room with dozens of 3D printers.

The first floor is also home to the maker classroom, a computer lab where workshops or special presentations can be held to learn new making-related skills.

There is also a materials exploration room, where students can get inspiration for their next project.

On the second floor is the textiles and electronics makerspace. This combines two areas of making, which has led to cross-disciplinary projects.

The textiles area is popular among students in the Cosplay and Anime clubs, who like to make their own costumes, said Jim Heaney ’23 (industrial engineering), the SHED’s makerspace technician.

Heaney said the ground floor, or A Level, is where students can get access to much more advanced equipment. There is an open workspace with hand and power tools and an array of 3D printers, including printers that use resin or carbon fiber.

The ground floor is also where there are two metal working shops, a woodshop, and where seven of RIT’s performance teams call home.

“I’ve only had great experiences using the makerspaces,” said Jordan Williams, a fourth-year mechanical engineering technology major. “All the machines are pretty self-intuitive, and the staff is always more than willing to help you achieve what you want to make.”

See what Williams and other students are making in the SHED.

Making at RIT has hit a new level now that several makerspaces in the Student Hall for Exploration and Development (SHED) have opened to provide students access to equipment and support for classwork, club advancement, and personal projects.

“It’s inspiring to witness a dynamic environment where students freely express their creativity and foster innovation,” said Tiffany Brodner, the SHED’s executive director.

The $120 million SHED, which opened last fall, is RIT’s biggest capital project since the campus moved to Henrietta, N.Y., in 1968. With its five extra-large classrooms, seven makerspaces, performing arts studios, and glass box theater, the SHED complex is made for a new generation of RIT students.

The makerspaces are spread across three floors. The first floor includes machines that can cut wood and plastic precisely with lasers, as well as a room with dozens of 3D printers.

The first floor is also home to the maker classroom, a computer lab where workshops or special presentations can be held to learn new making-related skills.

There is also a materials exploration room, where students can get inspiration for their next project.

On the second floor is the textiles and electronics makerspace. This combines two areas of making, which has led to cross-disciplinary projects.

The textiles area is popular among students in the Cosplay and Anime clubs, who like to make their own costumes, said Jim Heaney ’23 (industrial engineering), the SHED’s makerspace technician.

Heaney said the ground floor, or A Level, is where students can get access to much more advanced equipment. There is an open workspace with hand and power tools and an array of 3D printers, including printers that use resin or carbon fiber.

The ground floor is also where there are two metal working shops, a woodshop, and where seven of RIT’s performance teams call home.

“I’ve only had great experiences using the makerspaces,” said Jordan Williams, a fourth-year mechanical engineering technology major. “All the machines are pretty self-intuitive, and the staff is always more than willing to help you achieve what you want to make.”

See what Williams and other students are making in the SHED.

Greg Livadas

Photos by Carlos Ortiz

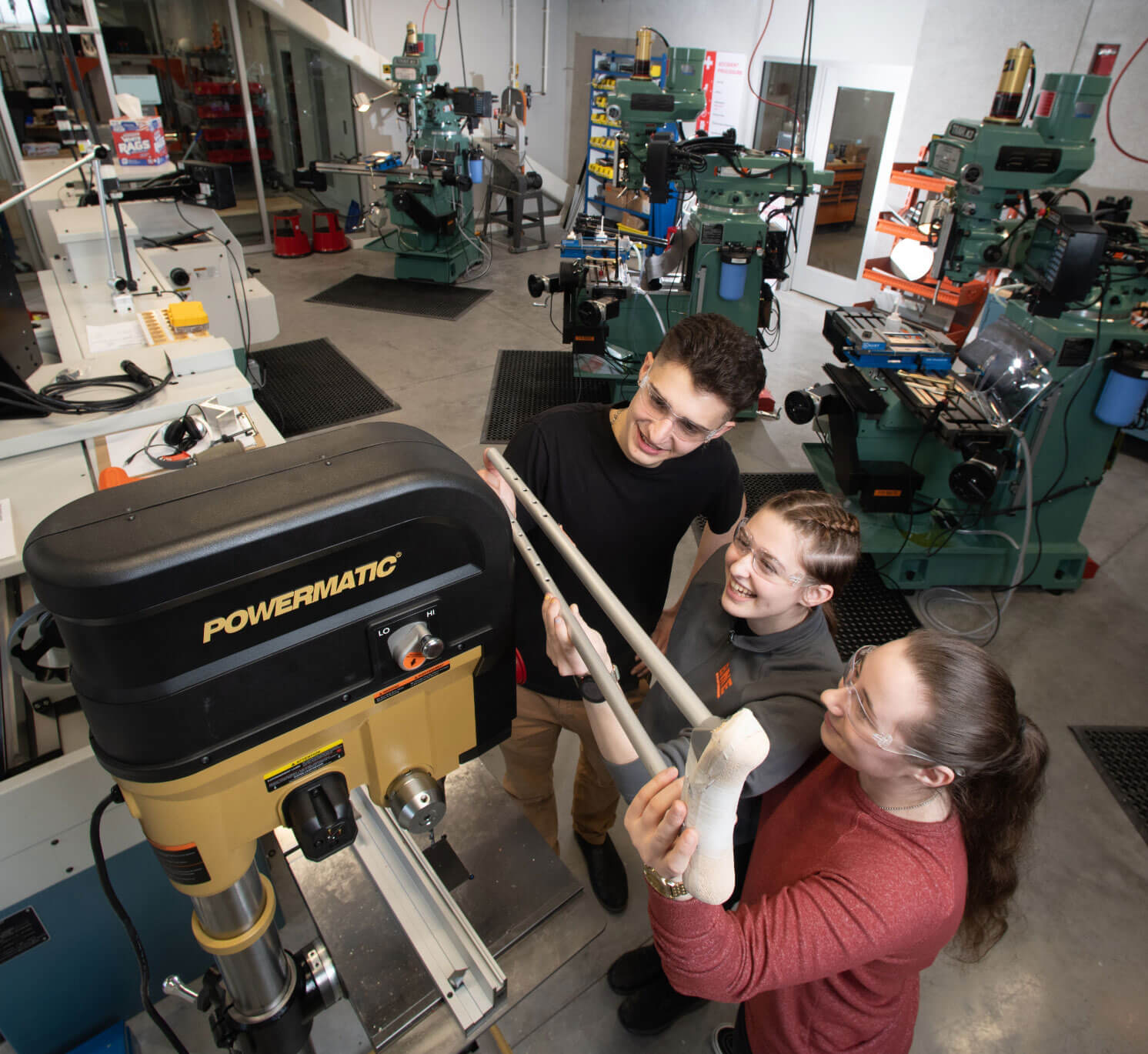

Adaptable smart crutch

The Adaptable Smart Crutch is a Multidisciplinary Senior Design capstone project that combines a modular crutch design with technology. By modifying traditional axillary and elbow crutches with sensors, physical therapists and their patients can benefit from knowing useful measurements, such as seeing the number of steps taken by patients, their distance traveled, and the percentage of weight applied on the crutches. The group is one of six classroom teams that worked in the SHED this semester. Team members include, from left to right, mechanical engineering major Matt McDermott from Canastota, N.Y.; biomedical engineering major Micki Geffert from Oxford, Conn.; and mechanical engineering major Julia Serchuk from Jericho, N.Y. All are fifth-year students.

3D-Printed Jedi Shuttle

A fan of Star Wars, Jordan Williams, a fourth-year mechanical engineering technology major from Williamson, N.Y., made more than 50 pieces on 3D printers over two semesters to construct an Ahsoka T-6 Jedi shuttle, which has a wingspan of nearly 3 feet when assembled. He also 3D printed hilts for lightsabers. He estimated the total printing of the items took 10 days.

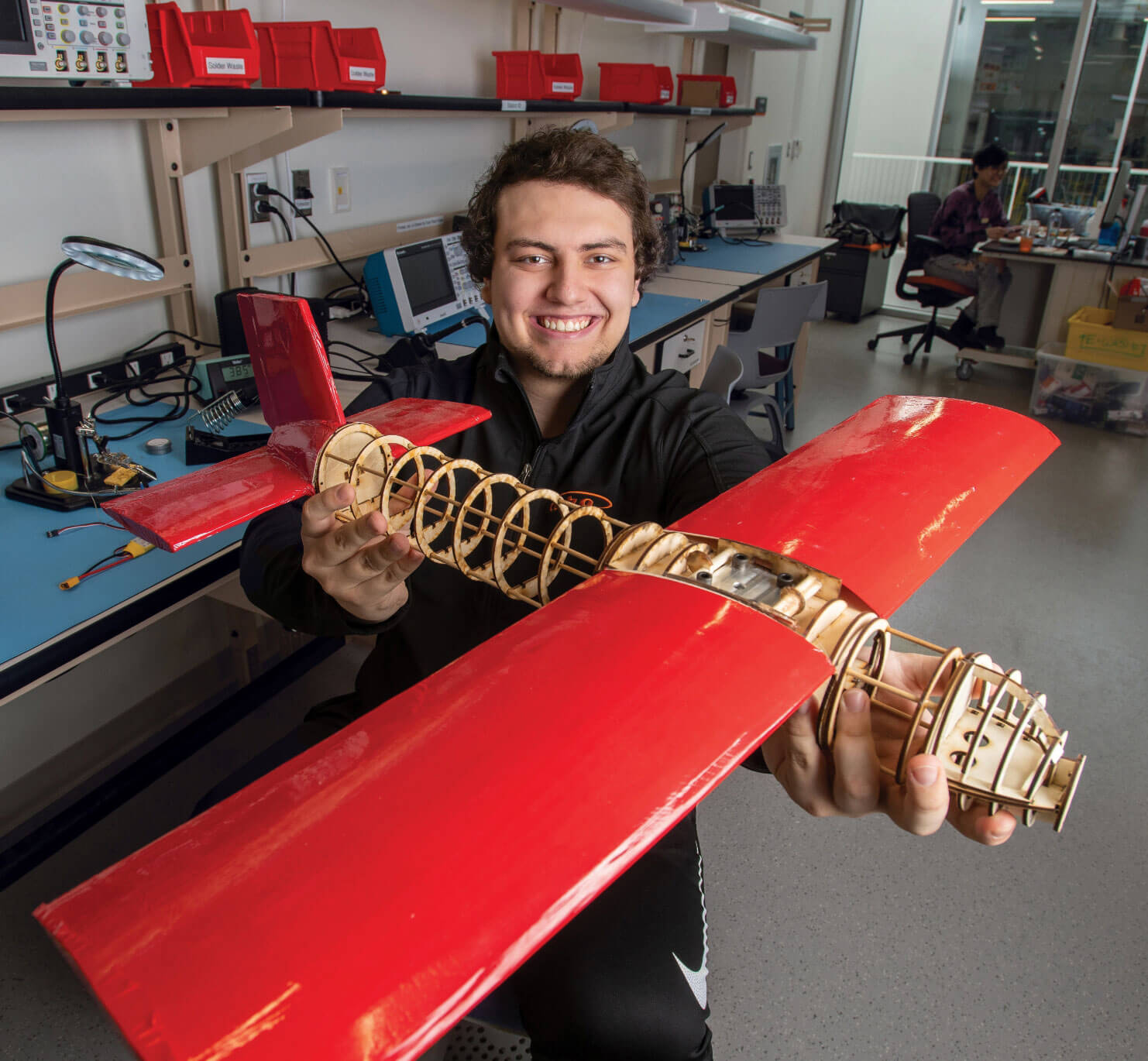

Remote-Controlled airplane

The 25 members of the RIT Aero Design Team use the space in the SHED to solder engine wires on their remote-controlled planes, which they’ll use in regional and national competitions. The SHED’s laser cutters are also used to help make parts for the planes. Brandon Badaszewski, a fifth-year electrical engineering and mechanical engineering double major from Blasdell, N.Y., is president of the club.

Brainwave wheelchair

RIT’s Neurotechnology Exploration Team (NXT), now based in the SHED, is working on improving accessibility for people with disabilities by enabling electric wheelchairs to move with brainwaves from the user. The team uses the SHED’s flexible classrooms for data collection trials, along with the project room. Project leader Alex Burbano, left, a fifth-year computer science major from Farmingdale, N.Y., said he is receiving credit for work on this research project through independent study. Charon Leu, right, a third-year mechatronics engineering technology major from Brooklyn, N.Y., is also a member of NXT.