Robotics and Manufacturing Engineering Technology Bachelor of Science Degree

Robotics and Manufacturing Engineering Technology

Bachelor of Science Degree

- RIT /

- Rochester Institute of Technology /

- Academics /

- Robotics and Manufacturing Engineering Technology BS

RIT’s robotics and manufacturing engineering technology major prepares you to become an engineer well-versed in advanced manufacturing technologies and automation.

$81K

Average First-Year Salary of RIT Graduates from this degree

72%

required courses in the College of Engineering Technology for this major have a lab component

Overview for Robotics and Manufacturing Engineering Technology BS

Why Study RIT's Robotics and Manufacturing Engineering Technology Major

A New Economy Major: Robotics and manufacturing engineering technology is an RIT New Economy Major. This collection of degree programs is forward-thinking and future-forming,and prepares you to excel in the multidisciplinary nature of our modern, dynamic economy.

Gain Real-World Experience: Four required blocks of co-op mean nearly a year of hands-on, full-time paid work experience in industry.

Jobs at Industry Leading Companies: Employers hiring our students for co-ops and full-time positions include AmazonRobotics, Apple, Tesla, Lockheed Martin, Amphenol Aerospace, GE, General Motors, ITT Corp, L3Harris and more.

A Choice of Focus Areas: Tailor your degree with a focus area in one of eight technical concentrations: design and assembly modeling, design for manufacture and assembly, data acquisition and instrumentation, electronics packaging, quality control, Lean Six Sigma, manufacturing management, or plastics processing.

Accelerated Bachelor’s/Master’s Available: Earn both your bachelor’s and your master’s in less time and with a cost savings, giving you a competitive advantage in your field.

STEM-OPT Visa Eligible: The STEM Optional Practical Training (OPT) program allows full-time, on-campus international students on an F-1 student visa to stay and work in the U.S. for up to three years after graduation.

Innovations in industrial automation and manufacturing robotics are creating an increased demand for highly skilled robotics and manufacturing engineers. RIT’s robotics and manufacturing engineering technology major prepares you to become an engineer well-versed in advanced manufacturing technologies. Right now, the demand for robotics engineers, manufacturing engineers, and those skilled in designing and integrating automation into manufacturing processes is outweighing the number of students graduating with degrees in robotics engineering, resulting in outstanding employment opportunities for our graduates.

Robotic Manufacturing

The future of robotic manufacturing has arrived. Today’s manufacturing industry has evolved, and its focus is now on advanced manufacturing technologies, which emphasize:

- Automation and advanced robotics to increase productivity and execute the precise maneuvers required to assemble small electronic parts.

- Big data and cloud computing to help manufacturers track and analyze trends and statistics, monitor productivity, and engage in data-supported decision-making.

- 3D printing to decrease waste and improve output, and to reduce the time needed for replacement parts.

- Artificial intelligence and the Internet of Things, which connects machines and devices and revolutionizes the way machines communicate and function.

- Augmented reality to create visual designs and simulations.

To meet the needs of the evolving manufacturing industry, RIT’s degree in robotics and manufacturing engineering technology focuses on preparing you to lead in this dynamic, ever-changing industry.

Robotics Engineering Courses

Students in the robotics and manufacturing engineering technology degree acquire skills in a wide variety of disciplines, including course work in automation and robotics, electronics manufacturing, mechatronics, advanced manufacturing technologies and processes, and integrated design. The degree’s comprehensive curriculum also includes traditional and non-traditional manufacturing processes, materials technology, computer-aided design, computer-aided manufacturing, controls for manufacturing automation, microprocessors, electrical and electronics principles, surface mount electronics manufacturing, quality control, lean manufacturing, engineering economics, and production and operations management. The uniqueness of this program is its combination of robotics and manufacturing courses and its emphasis on project-based, hands-on education.

Adding a minor in a complementary area of study deepens your expertise in the core areas of robotics manufacturing and broadens your skill set for a career in this dynamic field. These minors enhance the robotics and manufacturing engineering technology degree:

- Applied statistics

- Business analytics

- Computer science

- Cybersecurity

- Engineering management

- Manufacturing systems

- Plastics engineering and technology

- Surface mount electronics manufacturing

- Sustainable product development

High-Performance Teams and Professional Organizations

Many mechanical engineering students participate in high-octane performance teams, including the RIT Formula SAE Racing Team, the SAE Aerodesign Club, the RIT Baja SAE Team, RIT SAE Clean Snowmobile Team, and the Human-Powered Vehicle Competition team. They are also encouraged to participate in the student chapters of professional societies such as the American Society of Mechanical Engineers, the Society of Women Engineers, the National Society of Black Engineers, the Society of Hispanic Professional Engineers, the American Institute of Aeronautics and Astronautics, and the Society of Automotive Engineers.

Engineering vs. Engineering Technology

Two dynamic areas of study, both with outstanding outcomes rates. Which do you choose?

What’s the difference between engineering and engineering technology? It’s a question we’re asked all the time. While there are subtle differences in the course work between the two, choosing a major in engineering vs. engineering technology is more about identifying what you like to do and how you like to do it.

Combined Accelerated Bachelor's/Master's Degrees

Today’s careers require advanced degrees grounded in real-world experience. RIT’s Combined Accelerated Bachelor’s/Master’s Degrees enable you to earn both a bachelor’s and a master’s degree in as little as five years of study, all while gaining the valuable hands-on experience that comes from co-ops, internships, research, study abroad, and more.

- Robotics and Manufacturing Engineering Technology BS/Mechatronics and Mechanical Systems MS: Excel and lead the ever-changing world of automation and robotics through this accelerated dual degree pathway that combines the robotics and manufacturing engineering technology BS with the MS in mechatronics and mechanical systems. You'll deepen your engineering knowledge while you gain and career-ready business, management, and leadership skillsets that are part of the curriculum in the MS degree.

- +1 MBA: Students who enroll in a qualifying undergraduate degree have the opportunity to add an MBA to their bachelor’s degree after their first year of study, depending on their program. Learn how the +1 MBA can accelerate your learning and position you for success.

-

Join Us for Accepted Student Open House

Visit campus on March 28 or April 11 to meet faculty, tour campus, and ask your questions.

-

Join us for Fall 2026

There's still time to apply. For some programs, applications will be reviewed on a rolling, space-available basis.

Careers and Cooperative Education

Typical Job Titles

| Industrial Engineer | Manufacturing Engineering | Process Engineer |

| Robotics Engineer | Automation Engineer | Rotational Program in Manufacturing Leadership |

Industries

-

Aerospace

-

Automotive

-

Biotech and Life Sciences

-

Consumer Packaged Goods

-

Defense

-

Manufacturing

-

Telecommunications

Cooperative Education

What’s different about an RIT education? It’s the career experience you gain by completing cooperative education and internships with top companies in every single industry. You’ll earn more than a degree. You’ll gain real-world career experience that sets you apart. It’s exposure–early and often–to a variety of professional work environments, career paths, and industries.

Co-ops and internships take your knowledge and turn it into know-how. Your engineering co-ops will provide hands-on experience that enables you to apply your engineering knowledge in professional settings while you make valuable connections between classwork and real-world applications.

Students in the robotics and manufacturing engineering technology program are required to complete four co-op blocks. This typically includes one spring, one fall, and two summer blocks. You'll alternate periods of full-time study with full-time paid work experience in your career field. In some circumstances, other forms of experiential education (e.g., study abroad, research, military service) may be used to fulfill part of the co-op requirement. Each student is assigned a co-op advisor to assist in identifying and applying to co-op opportunities.

Featured Work and Profiles

-

Graduate Milks His Education and Creates Device to Help Dairy Farms

Jayden Neal '25 (robotics and manufacturing engineerign technology) will lead the development and manufacturing of the Vortex, a product to improve the milking process, in his family’s new business...

Read More about Graduate Milks His Education and Creates Device to Help Dairy Farms -

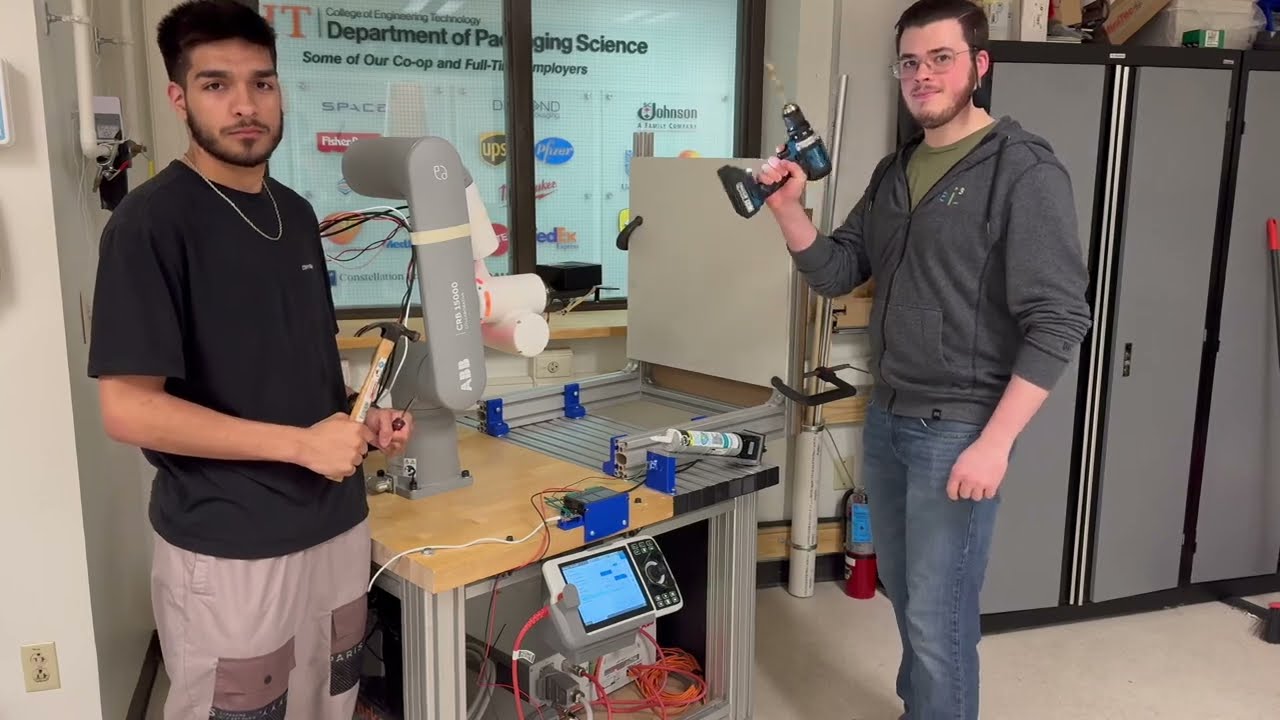

Students Use Robots for Flawless Surface Repairs

Two RIT engineering students employ a robot equipped with a vision system to detect and repair drywall defects, streamlining construction repairs with precision.

Read More about Students Use Robots for Flawless Surface Repairs -

RIT Researchers Push Boundaries of Human-Robotic Interactions

Ferat Sahin, Jamison Heard, Yangming Lee Several RIT faculty researchers are pushing the boundaries of human-robotic interactions.

Read More about RIT Researchers Push Boundaries of Human-Robotic Interactions -

Jet-Fueled Co-op Boosts Student's Manufacturing Career

Alison Fink Allison Fink’s co-op at Honda Aircraft deepened her passion for hands-on manufacturing, with impactful projects and exhilarating jet deliveries setting her on a dynamic career path.

Read More about Jet-Fueled Co-op Boosts Student's Manufacturing Career -

RIT Students Analyze Steel Microstructures in Metallography Course

First-year manufacturing and mechanical engineering technology students grind, polish, and etch steel samples to study grain structures and inclusions, gaining hands-on experience in metallographic...

Read More about RIT Students Analyze Steel Microstructures in Metallography Course

Curriculum for 2025-2026 for Robotics and Manufacturing Engineering Technology BS

Current Students: See Curriculum Requirements

Admissions and Financial Aid

This program is STEM designated when studying on campus and full time.

First-Year Admission

First-year applicants are expected to demonstrate a strong academic background that includes:

- 4 years of English

- 3 years of social studies and/or history

- 3 years of math is required and must include algebra, geometry, and algebra 2/trigonometry. Pre-calculus is preferred.

- 2-3 years of science. Chemistry or physics is required and biology is recommended.

- Technology electives are preferred.

Transfer Admission

Transfer applicants should meet these minimum degree-specific requirements:

- A minimum of college algebra is required. Pre-calculus or calculus is preferred.

- Chemistry or physics is required.

Financial Aid and Scholarships

100% of all incoming first-year and transfer students receive aid.

RIT’s personalized and comprehensive financial aid program includes scholarships, grants, loans, and campus employment programs. When all these are put to work, your actual cost may be much lower than the published estimated cost of attendance.

Learn more about financial aid and scholarships

Accreditation

Resources

Access Resources for students including academic advisors, student clubs and organizations, documents, technical information and support, and software help.

Related News

-

February 5, 2026

Co-op course helps students break into competitive industries

The Independent Professional Development course was developed last year to reflect fluctuations in the current job market and to support students who, despite their best efforts, have not yet secured co-ops.

-

November 4, 2025

Faculty members launch electronics manufacturing training for veterans

Two RIT faculty members are building a comprehensive workforce development program in manufacturing for veterans and under-employed individuals to provide the needed skills-based training in electronics assembly.

-

October 15, 2025

Researchers develop self-healing materials to improve 3D-printing processes

Self-healing materials are being developed by RIT researchers to further improve additive manufacturing, specifically 3D-printed products, to make them stronger and more resilient.

Contact

- Cecilia Creel Gomez

- Senior Staff Assistant

- Department of Mechanical and Mechatronics Engineering Technology

- College of Engineering Technology

- 585‑475‑2270

- cccmet@rit.edu

Department of Mechanical and Mechatronics Engineering Technology