Mechatronics and Mechanical Systems Master of Science Degree

Mechatronics and Mechanical Systems

Master of Science Degree

- RIT /

- Rochester Institute of Technology /

- Academics /

- Mechatronics and Mechanical Systems MS

Overview for Mechatronics and Mechanical Systems MS

Why Pursue a Mechatronics and Mechanical Systems MS at RIT?

STEM-OPT Visa Eligible: The STEM Optional Practical Training (OPT) program allows full-time, on-campus international students on an F-1 student visa to stay and work in the U.S. for up to three years after graduation.

Three Dynamic Options: Concentrate your studies in automation and robotics, computational mechanics, or product design and materials.

Future-Focused Curriculum: Learn from forward-thinking courses that integrate emerging technologies into modern industrial automation and design for manufacturing.

Top Hiring Partners: US Naval Research Laboratory; Tesla; Northrop Grumman; Micron Technology, Inc.; Intel Corporation; General Dynamics; Borg Warner; Bristol Myers Squibb; Fiat Chrysler Automobiles; Honeywell Aerospace; Keurig Dr Pepper; Siemens; Whirlpool

From collaborative robots on the factory floor to precision imaging technologies and advanced product design, modern engineering demands a new kind of expert—one with a mechatronics degree that allows them to understand the entire system, not just a single part.

RIT’s master of science in mechatronics and mechanical systems equips you with the interdisciplinary skills to design, develop, and optimize intelligent products and manufacturing systems that power the future. In this program, you’ll gain a deep understanding of:

- Core disciplines: electrical engineering, computer engineering, mechanical engineering

- Specialized skills: programming, systems design, manufacturing processes, robotics and mechatronics, and automation

- Cutting-edge technologies: imaging and sensing systems, artificial intelligence, and smart manufacturing

The program is offered by the department of manufacturing and mechanical engineering technology in collaboration with Saunders College of Business and the Kate Gleason College of Engineering.

Mechatronics and Mechanical Systems MS Courses

In RIT’s master's in mechatronics and mechanical systems, core courses are combined with extensive application and research opportunities and include:

- AI

- Lean Six Sigma

- Product design and production design

- Design of experiments

You'll also complete a four-course option, elective courses, and a capstone project, thesis, or comprehensive exam.

Options

Choose one of three options that match your interests:

- Automation and Robotics

- Courses in: Controls, Sensors, Vision, Automation, Robotics, AI/Machine Learning

- Computational Mechanics

- Courses in: Computer-Aided Engineering, Computational Fluid Dynamics, Multiphysics

- Product Design and Materials

- Courses in: Robust Design, Certified Design for Composite Product Manufacturing, Plastic Part/Products & Systems Development, Plastic Product Design

You may be required to take additional prerequisite courses depending on your background and the option selected. The graduate director may approve the waiver of courses in the prerequisite group from graduation requirements, depending on your academic and employment background.

Electives

Elective courses can be any course from a different concentration from the one chosen, a graduate-level course from another program (if approved by the graduate director and faculty member teaching the course), or an independent study course (if approved by the student’s graduate program director).

The number of electives needed to complete the mechatronics masters is based on whether you choose to complete a thesis, capstone project, or comprehensive exam.

- Thesis – Original research contributing to the field (requires 1 elective)

- Capstone Project – Applied industry or lab project (requires 2 electives)

- Comprehensive Exam – Demonstration of broad program mastery (requires 3 electives)

-

Affordable Now. Valuable for Life.

Earn your master’s degree without the full price tag. With Master Up you can receive a 30% tuition scholarship for an RIT master’s degree.

-

Join us for Fall 2026

Many programs accept applications on a rolling, space-available basis.

Careers and Cooperative Education

Typical Job Titles

| Applications Engineer | Automation Engineer | Design Engineer |

| Industrial Engineer | Manufacturing Engineer | Process Engineer |

| Product Development Engineer | Project Manager | Quality Engineer |

| Supply Chain Analyst |

Cooperative Education

What makes an RIT education exceptional? It’s the ability to complete relevant, hands-on career experience. At the graduate level, and paired with an advanced degree, cooperative education and internships give you the unparalleled credentials that truly set you apart. Learn more about graduate co-op and how it provides you with the career experience employers look for in their next top hires.

Full-time students are eligible to participate in RIT’s cooperative education program. After completing two semesters (a minimum of 18 credit hours), students may request approval to complete up to one year of cooperative education employment related to their field of study.

Featured Work and Profiles

-

Faculty-researcher is pioneering self-healing materials for 3D printing

Christopher Lewis Imagine a 3D-printed part that never needs replacement! We're pioneering self-healing materials for 3D printing. This groundbreaking technology, led by CET faculty researcher Dr. Christopher Lewis,...

Read More about Faculty-researcher is pioneering self-healing materials for 3D printing -

The Spark of Success: How Students Forged the First NYS American Welding Society Chapter

It took a spark of an idea from CET students to forge the first American Welding Society student chapter in New York State. The club now unites over 50 members from majors as diverse as engineering...

Read More about The Spark of Success: How Students Forged the First NYS American Welding Society Chapter -

NTID/CET Alumna Launches the Future of Tide and Gain as a P&G Engineer

Kayley Judd ’25 Kayley Judd ’25 landed a career solving the toughest problems that ensure global staples, like Tide and Gain, make it seamlessly from the factory to your laundry room. As a Fabric Care Packaging...

Read More about NTID/CET Alumna Launches the Future of Tide and Gain as a P&G Engineer -

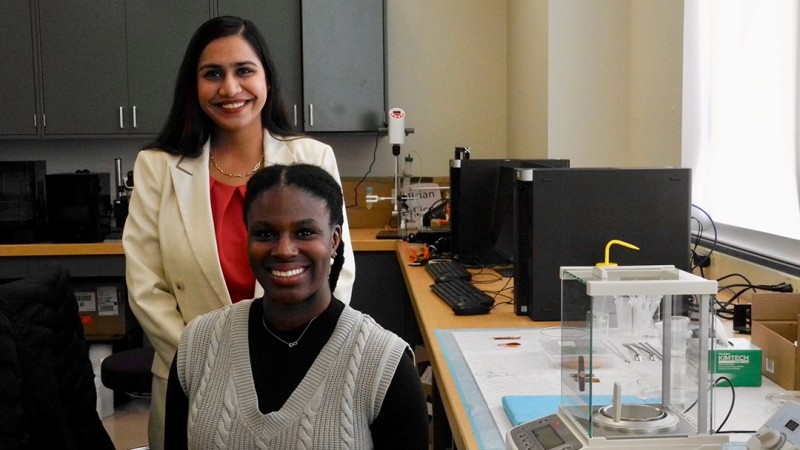

Student-Professor Duo's Cutting-Edge Prosthetic Sensor Research

Leila Daly, a fifth-year computer engineering technology student, is working with assistant professor, Krittika Goyal, to develop a sensor system for a more touch-responsive prosthetic finger that’s...

Read More about Student-Professor Duo's Cutting-Edge Prosthetic Sensor Research -

Robotic Solutions: Student Project

An RIT College of Engineering Technology student employs force feedback and vision systems on an ABB robot to simulate and optimize the grinding of dental tools.

Read More about Robotic Solutions: Student Project -

RIT Students Analyze Steel Microstructures in Metallography Course

First-year manufacturing and mechanical engineering technology students grind, polish, and etch steel samples to study grain structures and inclusions, gaining hands-on experience in metallographic...

Read More about RIT Students Analyze Steel Microstructures in Metallography Course

Curriculum for 2025-2026 for Mechatronics and Mechanical Systems MS

Current Students: See Curriculum Requirements

The MS in mechatronics and mechanical systems (formerly the MS in manufacturing and mechanical systems integration) has undergone an update to its curriculum. The revised degree combines engineering, robotics, automation, and computing to create smart products and manufacturing systems. You will have your choice of options in automation and robotics, computational mechanics, or product design and materials. The program will begin accepting students in fall 2026. Please contact the program chair for more information regarding curriculum, courses, and degree requirements.

Students are also interested in

Admissions and Financial Aid

This program is available on-campus only.

| Offered | Admit Term(s) | Application Deadline | STEM Designated |

|---|---|---|---|

| Full‑time | Fall or Spring | Rolling | Yes |

| Part‑time | Fall or Spring | Rolling | No |

Full-time study is 9+ semester credit hours. Part-time study is 1‑8 semester credit hours. International students requiring a visa to study at the RIT Rochester campus must study full‑time.

Application Details

To be considered for admission to the Mechatronics and Mechanical Systems MS program, candidates must fulfill the following requirements:

- Complete an online graduate application.

- Submit copies of official transcript(s) (in English) of all previously completed undergraduate and graduate course work, including any transfer credit earned.

- Hold a baccalaureate degree (or US equivalent) from an accredited university or college in the field of engineering, engineering technology, or computing. Students with degrees in other disciplines will be considered on an individual basis. A minimum cumulative GPA of 3.0 (or equivalent) is recommended.

- Satisfy prerequisite requirements and/or complete bridge courses prior to starting program coursework.

- Submit a current resume or curriculum vitae.

- Submit a personal statement of educational objectives.

- Submit one letter of recommendation.

- Entrance exam requirements: GRE required for individuals with degrees from international universities

- Submit English language test scores (TOEFL, IELTS, PTE Academic, etc.), if required. Details are below.

English Language Test Scores

International applicants whose native language is not English must submit one of the following official English language test scores. Some international applicants may be considered for an English test requirement waiver.

Duolingo (DET): 120

IELTS: 6.5

LanguageCert Academic: 70

PTE Academic: 56

TOEFL: 79/4.5

International students below the minimum requirement may be considered for conditional admission. Deaf and hard-of-hearing test takers with significant hearing loss do not need to take the listening and speaking sections for the TOEFL and IELTS. Each program requires balanced sub-scores when determining an applicant’s need for additional English language courses.

How to Apply Start or Manage Your Application

Cost and Financial Aid

An RIT graduate degree is an investment with lifelong returns. Graduate tuition varies by degree, the number of credits taken per semester, and delivery method. View the general cost of attendance or estimate the cost of your graduate degree.

A combination of sources can help fund your graduate degree. Learn how to fund your degree

Additional Information

Bridge Courses

- Applicants without a robotics background who want to do the robotics concentration will be assigned additional bridge courses.

- Applicants without a modeling background who want to do the advanced mechanics concentration will be assigned additional bridge courses.

Accreditation

Related News

-

January 14, 2026

RIT engineering technology professor becomes president-elect of ASEE organization

RIT professor Martin Gordon was recently voted president-elect of the American Society for Engineering Education.

-

April 7, 2023

Engineering technology student upgrades industrial robot to be used for future classes

Pete Van Camp played detective before he acted as a manufacturing engineer for his graduate capstone project. His project involved upgrading a Fanuc industrial robot, which had been sitting idle for a short time in the Fabrication and Robotics Lab located in RIT’s College of Engineering Technology. Limited documentation about functions, missing cables and components, and fewer technical people from the company to provide service support were just a few of the barriers Van Camp encountered as he began.

-

August 17, 2022

RIT Combined Accelerated Bachelor’s/Master’s Degree student enrollment steadily increases

There are 740 new RIT students enrolled in the Combined Accelerated Bachelor’s/Master’s Degree program, designed to offer highly focused, goal-oriented incoming students a one-of-a-kind opportunity to work toward a bachelor’s and master’s degree, starting from the first day of classes.

Contact

- Bethany Iraci-McBane

- Assistant Director, Graduate Admissions

- Graduate Admissions

- Enrollment Management

- 585‑475‑5235

- bimges@rit.edu

- Cecilia Creel Gomez

- Senior Staff Assistant

- Department of Mechanical and Mechatronics Engineering Technology

- College of Engineering Technology

- 585‑475‑2270

- cccmet@rit.edu

Department of Mechanical and Mechatronics Engineering Technology